A significant portion of Australian enterprises are in manufacturing. BatchMaster Manufacturing ERP for Microsoft Dynamics GP is a comprehensive ERP solution that helps manufacturers deal with recipes and formulas to make manufacturing simpler for those companies. This strong solution gives consumers the ability to

- Work in a unified environment using the same GP interface.

- Use the same credentials to log in, and

- Work on a single database to improve communication

This manufacturing ERP integration with Microsoft Dynamics GP allows seamless & secure data exchange between the BatchMaster Manufacturing modules and the Microsoft Dynamics GP inventory, sales, and purchase modules. As a result, manufacturers can now benefit from the automation of formulation, batch processing, product development, material planning, and other organizational processes.

For manufacturing industries, BatchMaster ERP with Microsoft Dynamics GP supports all departments at all stages of production. This guarantees effortless financial statement generation and consolidation, enhanced decision-making and cash flow, decreased waste, and greater ROI!

Benefits of BatchMaster Manufacturing for Microsoft Dynamics GP

Complete System

For all manufacturing-related operations, including R&D, formulation, inventory planning, batch processing, compliance, finances, and more, this Manufacturing ERP with Microsoft Dynamics GP proves to be a one-stop solution.

Less Customization

The solution has a full set of specialized tools to fit your company standards and needs, which eliminates the need for further customizations and integrations. The needs of all the following industries and sub-industries such as: paints and chemicals, food and drinks, personal care and cosmetics, pharmaceuticals, etc. are fulfilled by BatchMaster ERP with Microsoft Dynamics for Manufacturing Industries.

Control over cost & loss

The system gives manufacturers the ability to plan ahead and schedule work in a way that ensures total optimization of all process cells, timely procurement, avoidance of overstocking, and tracking of shelf-life and expiration dates.

Increased revenue

The dashboard, reports, charts, and "smart lists" provided by BatchMaster keeps you updated with the right information (of available-to-promise, on hand and sales figures), consumer analysis, and market trends so that you can communicate appropriately to your vendors, prospects, and customers, which helps in increasing profitability.

Diversified tools unified software

A powerful and common platform equipped with a wide range of distinctive and diversified modules, BatchMaster Manufacturing for Microsoft Dynamic GP helps organizations streamline the entire manufacturing process. The general ledger is updated each time a material is issued for production, and the system instantly generates a report on items that are essential but insufficient for production. Moreover, when materials go through quality control, your quality control manager is informed.

Adherence to compliances

The system complies with all required standards, best practices, and Australian region-specific compliances. It effectively handles allergens, generates standard labels, permits SOP attachments, which aids in proper reporting and disposal of hazardous products, transports the materials in accordance with GMP, and tracks materials along the value chain—back and forth.

Improved and Quicker ROI

At BatchMaster, our skilled professionals carry out flawless and systematic implementation while closely adhering to your budget and deadline. Businesses all around the world rely on BatchMaster because it consistently releases updates in response to shifting market trends, offers system scalability in response to company expansion, and accommodates new industry laws. Allowing employees to operate on the same Microsoft interface and with the same set of Microsoft GP tools which will cut down on the need and time of training, thus securing profits for businesses in their bags.

More Productivity

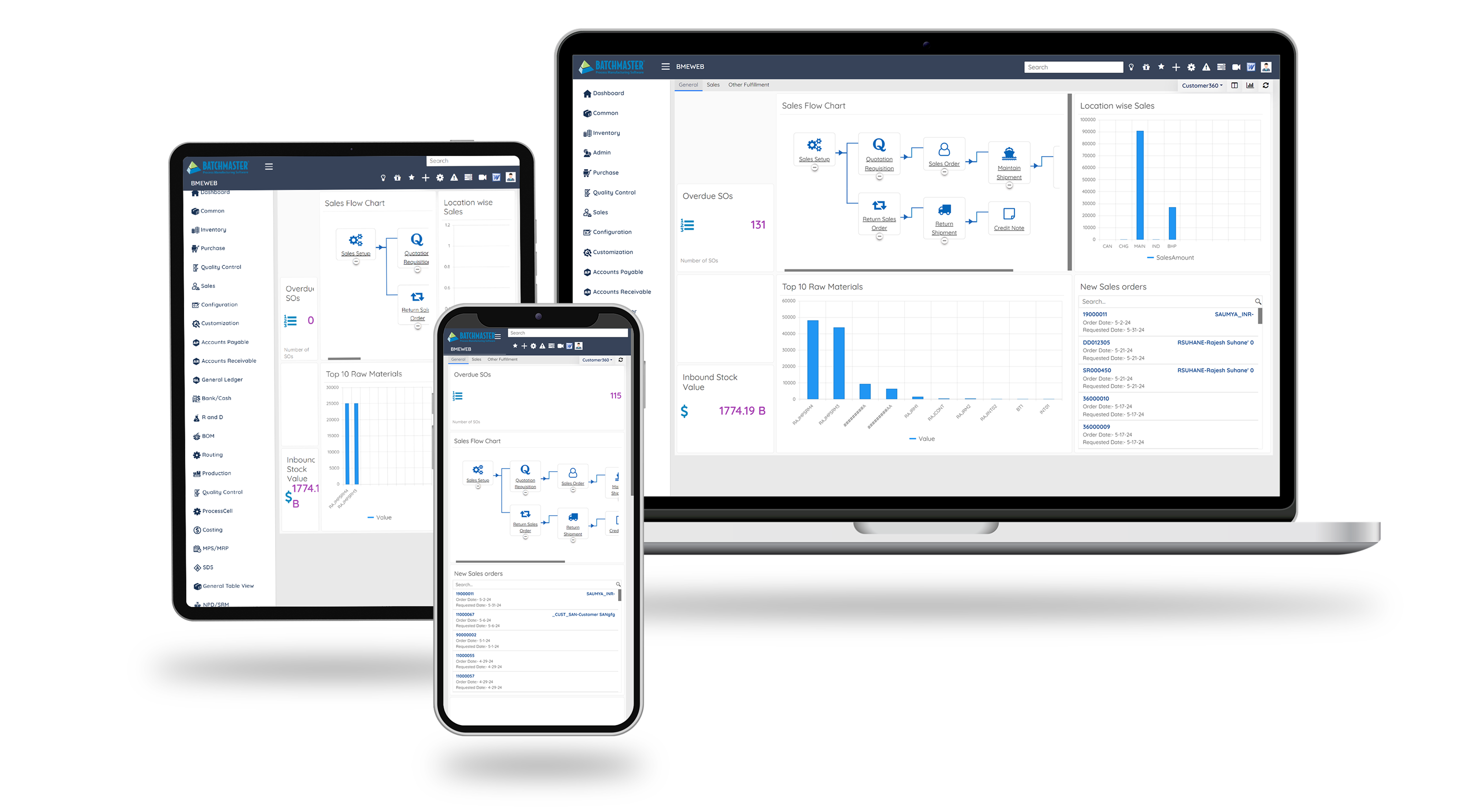

BatchMaster Manufacturing ERP shares a single interface, login, and database with Microsoft Dynamics GP for Manufacturing Industries in Australia and New Zealand. Having cooperatively produced, comfortable and shared workspace for employees that allows them to work and use simple Microsoft technologies to effectively build their own independent and connected worlds. This will allow employees to arrange their own responsibilities under one roof of work. In addition to these, improved operations & communication increase productivity inside your company.

Robust Modules of BatchMaster Manufacturing ERP

Formula & Recipe Management

Streamline the complete production for process manufacturers by managing formulas well. For this, use BatchMaster ERP to grant the required approvals at each level, right from R&D to approval. Version control and rollback, formula sizing, material replacement, loss and cost analysis are just a few of the features the system is capable of.

Cost Analysis

There is no need to worry about production costs because BatchMaster ERP can easily undertake a cost analysis of the entire process, separately as well as combined for both production and packaging. Managers can conduct what-if analysis, target price achievement, cost comparison, and execute analysis based on standard, market, average, and last cost & base price thanks to the costing module of the software.

Laboratory Module

Manufacturers get total control over the intricate laboratory operations that deal with physical properties, calculations, and production insights, all thanks to BatchMaster ERP's integration with MS Dynamics GP. With the help of this lab module, you can do multiple equations, analyze physical properties using target values, compare physical properties, and perform property roll-up operations. Along with effective tracking and costing, BatchMaster ERP also enables opportunity and sample management.

Production Module

Take advantage of cutting-edge modules like SuperBatch, which facilitates the production of both intermediate and finished goods in the same batch, and BatchWithRuns, which makes it possible to divide huge batches into small, distinct, and executable chunks. It streamlines the production with the convenience of anytime batch sizing, batch replacement, BOM sizing, partial and complete closure, batch inspection, and weight/volume analysis.

Compliance & Report Management

Manufacturers can manage all their tracking and tracing requirements just with a special feature provided by BatchMaster ERP - Smart lists. Deeper insights and essential information are provided via robust reporting, analytical tools, and dashboards, ensuring effective and rapid decision-making.

Quality Check

It is possible to complete a full quality analysis from raw materials through production to ensure an error-free production process. Processes like associating quality tests with anticipated results, supporting various types (pass/fail, numeric & alphanumeric), retesting with a provision for destructive testing, and avoiding unqualified materials are all possible with such an effective QC tool.

MSDS

By adhering to GHS and carrying out hazard communication initiatives, the possibilities of chemical-related occupational diseases and injuries can be reduced. MSDS includes a full range of capabilities that are made to automatically create shipping documents, labels, SARA reports, and safety data sheets.

MPS/MRP

With these upgraded tools from BatchMaster ERP, you can ensure the accuracy of your production and purchasing plans. With the use of MPS & MRP, manufacturers may determine the quantity of raw materials, labor, and machinery needed to produce a specific number of products.

Integrate. Extend. Excel.

Cloud Deployment Available

Give your small, mid-size, or large-scale businesses the power of our ‘Cloud ERP’ solutions, and enjoy the benefits of leveraging the cloud.

See BatchMaster ERP in Action

Allow our expert team of solution consultants to review your business operations so that they can offer you the best-possible solution, either on premise or in the cloud, to meet all your industry-specific needs

BatchMaster Software is one of the market leaders in offering enterprise software solutions for the process manufacturing industries. With an in-depth industry analysis, gained through a vast industry experience with over 2000 implementations worldwide, we clearly understand the unique industry challenges. BatchMaster offers ERP solutions that are apt to support industry specific operations and handles critical processes of the micro-verticals. Process manufacturing companies around the globe have come to rely upon BatchMaster® to manage nearly every aspect of their manufacturing distribution, finance & accounting, Quality Control, Compliance and HR- related operations. With headquarter in Laguna Hills, BatchMaster has its offices in New Jersey, India and New Zealand.