BatchMaster Manufacturing for SAP Business One

Harness the power of the best combination ever for recipe-based/formula-based manufacturers!

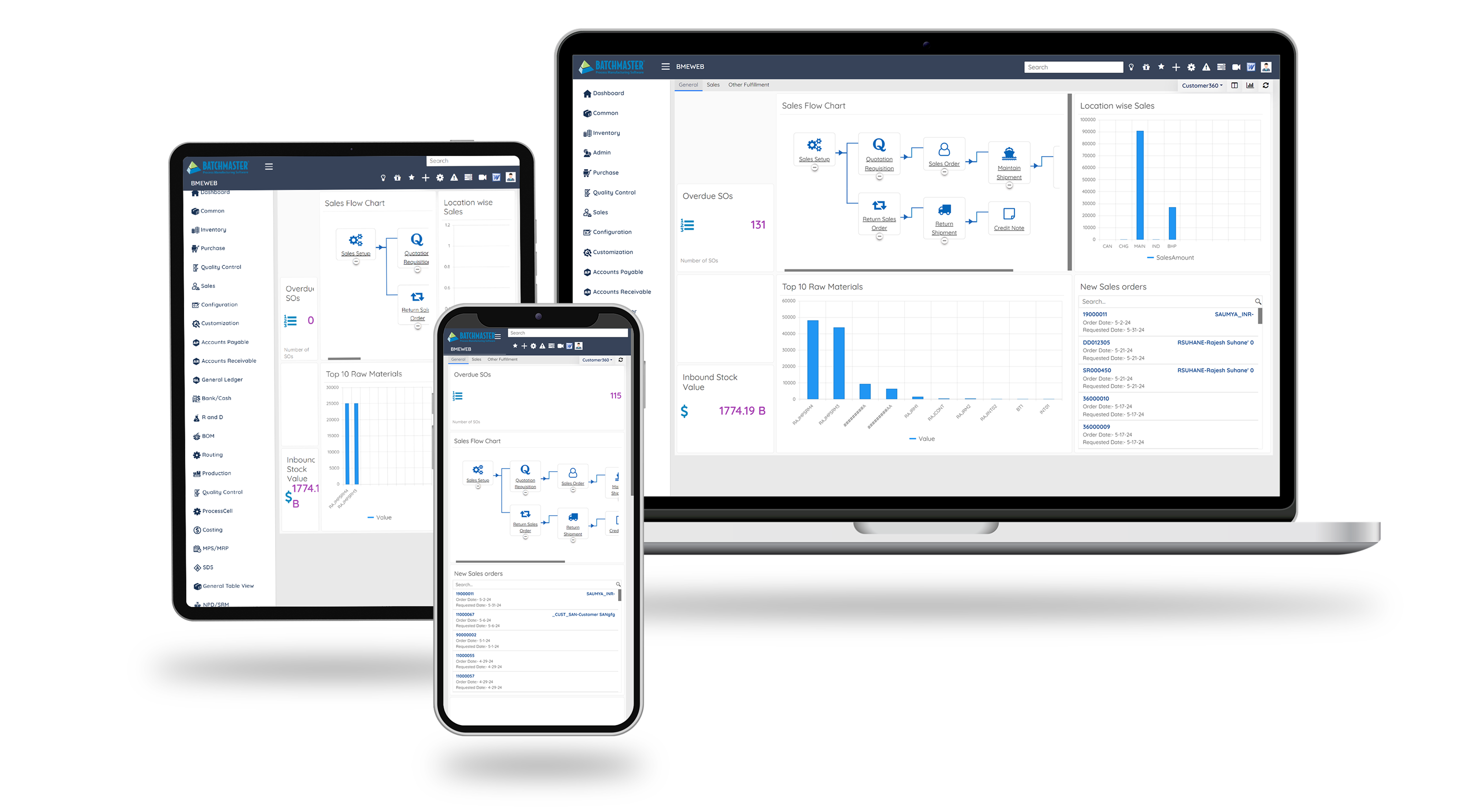

Run your business and ascend smoothly along the growth trajectory with BatchMaster Manufacturing for SAP Business One – a process manufacturing ERP integrated with SAP Business One for manufacturers in Australia and New Zealand. BatchMaster Manufacturing is built into SAP Business One ERP Software, where the Sales, Purchase, Inventory, and Finance modules of SAP Business One work in perfect cohesion with the process manufacturing modules like R&D and Formulation, Costing, Batch Processing, Quality, Compliance, and others of BatchMaster Manufacturing that makes your business more streamlined, more agile, more resilient, and more productive.

One Complete Solution

BatchMaster Manufacturing for SAP Business One is an end-to-end solution for emerging needs of formula-based or recipe-based manufacturers.

User-Friendly GUI

Equipped with the same GUI, same login, and single database of SAP Business One, it gives an edge with features like Google-style search, connection maps, notifications, and workflows.

Contemporary in its Approach

Continuous development in the product space to keep pace with the changing trends, regulations, industry practices, technology, not only for Australia and New Zealand, but worldwide.

Specially Tailored For Your Industry

Your industry is special and so is your requirement. Our product is designed to meet the real complexities of your industry.

Adheres to Industry & Regulatory Compliance

BatchMaster Manufacturing for SAP Business One by design helps you comply with customer, industry, and federal regulatory requirements like COA, FDA, GHS, FSSAI, FSMA, EPA, and more.

BatchMaster SAP Business One ERP Add Ons

The performance of BatchMaster Manufacturing for SAP Business One can be enhanced with the help of specially designed add-ons that cater to specific business needs with:

- BatchMaster WMS powered by SAP Business One: Supports remote inventory control with various handheld devices.

- Bin Management: Manages and streamlines inventory meticulously by tracking and managing inventory up to bin level.

Why BatchMaster Manufacturing for SAP Business One?

- Built on a strong foundation of SAP Business One

- Supports and documents the complete supply chain

- Provides industry-specific solution to cater to its unique needs

- Helps adhere to the regulation and best practices

- Enables real-time information flow

- Provides a sneak peek of cost vs production matrix

- Enables easy progress tracking

- Helps in informed business decisions

BatchMaster SAP Business One ERP Modules

BatchMaster Manufacturing for SAP Business One is a single platform developed with a holistic approach to cater to the peculiar needs of:

BatchMaster Manufacturing for SAP Business One, developed for the Australian manufacturing industry, provides a number of formula management capabilities, including:

- Formula comparison

- Version control for tracking formula changes

- Rollback to regain the saved/previous version of the formula

- Sizing the formula by weight or volume

- Material substitution based on weight or volume percentage, material availability, and more.

- In-process quality checks for better formula quality management

- Formula analysis with various cost options available

- Support to multilevel formulas

- Intermediate expansion to replace the intermediate or by-product involved within the formula

The Bill of Materials (BOM) depicts a detailed and hierarchical view of the finished product, beginning with the raw materials used and progressing through intermediate materials, packaging materials, and so on. It connects the formula to the completed goods or intermediates and lets you define routing. It has the following features as well:

- Comprehensive Bill of Materials functionality

- Encloses top-level BOM item

- Flexibility to define ‘Fill Level’ in the desired unit of measurement

- Routing functionality to ensure a flawless production process

- Support to multiple packaging options

- Bill of materials report to classify the top assembly items, assembly types, and status of the BOM components associated with the formulas

- Caters to both Process (Formula BOM) and Discrete (Assembly BOM) manufacturing need

- Provides a full view of the BOM hierarchy

- Single BOM allocation with multiple formulas

The module aids you in safely converting your formulas into more effective and preferred versions. It has a range of features, including interactive research of physical properties of formulas, and a number of additional features, such as:

- Intermediate Property Rollup Utility- Keep the specifications of your intermediates current according to the formulations

- Comparative Properties Analysis – Conveniently compare several formulas and products side-by-side from the same screen

- Physical Property Formula option- Create completely new physical properties based on the combination of material specifications and operators available

- Physical Property Analysis option- Overcome the hassles of creating a new formula from scratch

- Reduce the time and effort invested in the R&D of new formulas

BatchMaster Manufacturing for SAP Business One improves compliance efficiency for manufacturing organisations with the following functions, allowing them to proactively comply with FDA and GMP requirements.

- Supports Data Ownership Authorisation

- Generates Nutritional Labels/Nutritional Information Panel using different serving sizes and units of measures

- Generation of Ingredient Statement, quantity and percentage-wise

- Reports for

- FDA Audit

- Quality Control History

- Lot Tracking

- Transaction

- Lot Explosion

- Embedded forward and backward lot-traceability feature

- Generates Lot Recall Letter

- Offers Lot Strength functionality to calculate potency of the product

- Attach Standard Operating Procedures

- Closed-loop process that maintains FDA 21CFR Part 11, cGMP, Bioterrorism Act etc.

The production module offers comprehensive capabilities that streamline the entire process from start to finish. It seamlessly integrates with operations and provides instant access to real-time data, enabling it to efficiently manage various processes such as mixing, filling, and assembling components. Key features include:

- Production Scheduling Dashboard -Expedite production scheduling and generate real-time information faster than ever before

- Streamline batch sizing, which improves the accuracy of inventory and costing functions immensely

- Super Batch- Resolve the common process manufacturing necessity of producing a batch and its low-level intermediates in a single operation

- Track running totals of finished goods and by-products produced and consumed

- Update costs and inventory in real time upon batch closure

The fully integrated Lot Traceability function in BatchMaster Manufacturing for SAP Business One accurately tracks the forward and backward movement of raw materials, intermediates, and finished goods throughout the entire supply chain. This enables producers to meet compliance requirements more effectively and stay audit-ready at all times.

- Manage any recall situation in a fraction of the time

- Reduce response times to potential complications, ultimately ensuring brand security

- Guarantee transparency across the value chain, from ingredients to consumer goods

- Gain a 360-degree view of a product lot’s activity

- Ensure each lot remains distinct in subsequent operations

- Comprehensive lot traceability with container-level tracking of source supplies

Enhance your organisation’s quality assurance. Our accurate, quality-focused solutions help you achieve optimal quality control at every stage, from sourcing raw materials to manufacturing intermediates or finished goods, and inspecting final goods before shipping them to customers.

This fully integrated quality control system tracks pass or fail statistics based on an unlimited number of user-defined criteria and enables you to accept or reject products based on inspection results.

- Well-defined QC functionality to receive, produce, and ship products that meet customer and compliance requirements

- QC test and sample definition plus the ability to determine the target values, control limits, and maximum allowable defects

- Accomplish the QC sampling process with Pass or Fail results, Alphanumeric as well as Numeric values

- Immediate and counteractive action, like destruction, return, etc., can be taken against the items that fail QC Inspection

- Track the faulty materials and consign them for return to the vendor, scrap, or rework

- Supports the tracking of production quality, expiry date, shelf-life period, and lot-controlled products

- Reporting the QC results for Raw Material, Intermediate, and Finished Good Items

The Costing module in BatchMaster Manufacturing empowers you to determine the most reliable, accurate, and profitable price for your products. It enables you to analyse formula and finished product costs from multiple perspectives and at varying levels of detail.

Understand how labour, overhead, materials, and packaging contribute to your product’s total cost. Adjust the quantity of any material to conduct a “what-if” analysis and evaluate profitability across various scenarios based on different assumptions. Instantly see how these changes impact the overall costs.

- Collaboratively analyse costs associated with the manufactured products

- Establish gross margin based on costs and selling price

- Revise formula loss factors to accomplish better accuracy

- Calculate Sales Price and Standard Cost based on the cost of ingredients

- Revaluate the actual cost of the finished good or intermediate inventory

To minimise overburdening situations, identify production contractions based on predicted deliveries, and allocate resources appropriately. The Production Scheduling Board is an all-in-one solution that simplifies production scheduling. You may monitor and analyse production floor stocks and resources using a dynamic graphical user interface that clearly displays batches with various statuses using separate colour codes.

- Reschedule the batches just by dragging them to the preferred schedule date, on the Schedule Calendar grid

- Define tasks that need to be executed apart from the routine production jobs

- Interactive month, week, and day views provide flexibility to swiftly organise the batches accordingly

- Quickly list the batches and illustrate their relationship to one another using the Gantt Chart View

- Zoom in the Schedule Calendar Grid of the Production Schedule screen and get details of the process cell attached to the existing Batches/Orders/Task

- Regulate planning and scheduling of activities on the shop floor

You may utilise your skills to flawlessly plan and control the production process using the Routing module. In the production process, specify the order in which work centres are used. Quick Labor Entry can be used to create a list of staff and machine details, as well as their preparation and processing times. When it comes to categorising manufacturing routes, the routing module is an excellent place to start.

- Designate shifts available by weekdays in which the selected employee will be working

- Define and generate schedules for a range of employees for selected working days

- Plan and manage resources by interpreting the schedule of a given work centre over a week’s span using the Work Centre Capacity Utilisation option

- Add routing to a particular BOM just by implementing very easy setup options

- Cope with item routings by means of the Routing tab present on the Batch Ticket form

- Firmly retain completion time and quantities related to production batch by means of various routing facilities

BatchMaster Manufacturing for SAP Business One enables multi-site manufacturers to manage their bins. All business operations, including sales, purchasing, and production are managed at the bin level rather than at the warehouse level. This feature guarantees that merchandise is handled with care before being placed in the bag. For any inventory transaction, you can see a real-time display of products in stock. You’ll be able to keep track of inventory more quickly and precisely if you keep it in multiple bins.

- Track inventory bin-wise, item-wise, warehouse wise, lot wise or container wise

- Support multi-location inventory feature to organise your warehouse or multiple warehouses

- Get an instant view of various bin transactions, such as Container, Bin Number, Issue/Receipt Quantity, etc.

- Handle non-tracked inventory with ease at the bin level

- Manage various Storage Conditions for bins and items

- Warnings for older lots and duplicate lots

- Expired lots calculation for issue transactions

By identifying what to order, when to order, how much to order, and when to plan an order’s delivery, BatchMaster’s MRP module aids production managers in scheduling and placing orders for dependent-demand items, as well as ensuring a flow of materials required for production.

- Ensure material availability and increase planning stability

- View production bottlenecks at a glance with an interactive graphical vision

- Reconcile the customer requirements with plant capacity, material availability, and vendor capabilities

- Support in evaluating the effects of schedule changes in the short run

- Perform scheduling on a single or a range of items and warehouses

- Spontaneously create a Purchase Order for the re-sale type of item

- High stock levels and reduces storage costs

- Last-minute rescheduling and efficient allocation of resources

- Planning Time Fence to protect the master plan from spontaneous changes

- Adjust dates of planned orders that fall within the planning time fence

Set a timeline for creating things, sourcing supplies, and adding value to the production process as soon as possible. BatchMaster can help you create and maintain an effective manufacturing plan based on sales forecasts, purchase and production orders, inventory statuses, and work orders with a comprehensive bill of materials. Its implementation ensures that production materials are available and that products are ready for shipment. By considering the BOM and time fencing supplies with the indicated average lead times, BatchMaster MRP assists you in determining material requirements.

- Streamline the production operations and minimise unplanned interruptions to improve performance

- Confidently sustain with the lowest possible material and product level in stock

- Generate purchase orders from net demand relative to reorder levels

- Align existing jobs with changes to required dates

- Support the top, bottom, and smart level explosion

- Support to meet the delivery schedule, purchase activities and plan orders

- Avoid delays in material procurement, production and decision making

- Cost of excessive inventory can be reduced

Run Our Manufacturing ERP With Your Existing Financials

Upgrade to our ERP without missing a beat in your financial and accounting routines. BatchMaster ERP offers seamless integration with Tally, QuickBooks, Sage 50/100/200/300, SAP Business One and other popular systems, ensuring a smooth transition.

Brochures

Web/Cloud Deployment Available

Give your small, mid-size, or large-scale businesses the power of our ‘Cloud ERP’ solutions, and enjoy the benefits of leveraging the cloud.

Looking To Find the Best Solution for Your Business?

Allow our expert team of solution consultants to review your business operations so that they can offer you the best-possible solution, either on premise or in the cloud, to meet all your industry-specific needs