ERP for Pharma Manufacturing Industries

What are the Major Challenges Faced by the Australian Pharmaceutical Industry?

Healthcare reforms, increasing market demands, and stringent regulatory pressures are significant challenges for pharmaceutical manufacturers in Australia and New Zealand. Patients and regulators alike expect higher standards of care at lower costs, all while demanding greater transparency.

To address these challenges, it’s becoming increasingly essential for pharmaceutical manufacturers to take a proactive approach to compliance and product safety, while also meeting market demands—using ERP software designed for the pharmaceutical industry. Without a Pharma ERP system, manufacturers in Australia and New Zealand struggle to manage their operations efficiently.

Schedule a Demo of BatchMaster Pharma ERP Software

Pharmaceutical Industry

Why Pharmaceuticals Manufacturing Businesses Require ERP Software?

BatchMaster ERP for Pharmaceuticals is a comprehensive, out-of-the-box pharma ERP solution that meets the unique demands of pharmaceutical businesses globally. Specifically designed for the pharmaceuticals industry, this software helps Australian manufacturers stay compliant with cGMP requirements and develop a cost-efficient business model.

As a specialised ERP for the pharmaceutical sector, it fully understands formulation management needs and integrates key business operations to provide real-time information.

In this way, BatchMaster ERP software for pharmaceuticals helps Australian manufacturers streamline their operations and take proactive steps to stay ahead of the competition.

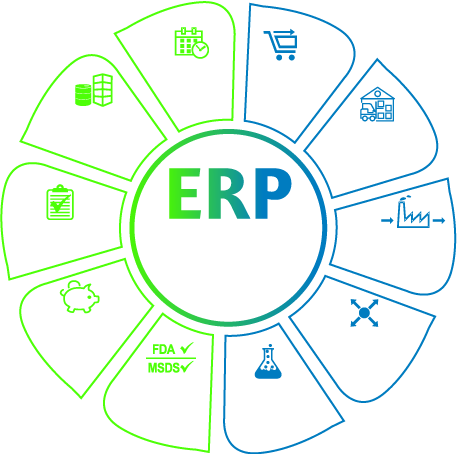

Capabilities Offered by BatchMaster ERP for Pharmaceuticals Industry

The BatchMaster ERP software for pharmaceuticals offers a range of robust capabilities tailored for pharma manufacturers:

- Formula Management: BatchMaster sets the benchmark in formula management. It provides comprehensive control over formulas, ensuring security, patenting, version control, and the ability to compare different formula variations seamlessly.

- Batch Resizing: Pharmaceutical ERP system feature empowers users to adjust batch sizes in alignment with available raw materials or specific order sizes, ensuring optimal production.

- Labelling and Traceability: Addressing crucial industry requirements, the pharmaceutical software facilitates chemical content labelling and bi-directional traceability. Moreover, it generates essential reports such as FDA reports, BMR (Batch Manufacturing Record), MBR (Master Batch Record), COA (Certificate of Analysis), adhering to standard formats.

- Inventory Optimisation: Effectively manage, label, and track inventory using various methods such as LIFO (Last In, First Out), FIFO (First In, First Out), FEFO (First Expired, First Out), while also managing shelf life and expiration dates efficiently.

- SuperBatch: An innovative feature allowing the launch of intermediate and finished goods in a single batch, maintaining the required chronological order without the need for separate launches.

- Item Physical Properties: An ERP in pharma enables users to define and manage unique physical characteristics of finished goods, including attributes specific to various product types such as soft gel capsules, tablets, and more.

Essential ERP Modules for Pharmaceuticals Manufacturing Industry

Key Features of Pharmaceuticals Manufacturing Software

- Pharmaceuticals ERP system offers Formula Management with Formula Security, versioning with audit log and Approval for revised formulations

- By-product & co-product management

- Master Production Scheduling (MPS) & Material Requirement Planning (MRP)

- Raw material/product specifications

- Supplier management and qualification

- Separate granular costing of formula and packaging material

- Pharma ERP solution supports Contract Manufacturing

- Opportunity tracking and new sample management with real costs and quotations

- Bi-directional lot traceability & lot recall

- Quality control (QC) with sampling plan, stability testing

- Quality assurance (QA) as per cGMP norms

- Batch monitoring activities by inspection plan

- Electronic execution of SOPs by inspection checklist

- Electronic batch ticket and electronic weigh sheet

- Inventory management

- Non-conformance (NC), adverse event reporting and corrective and preventive action (CAPA)

- Manufacturing batch record (MBR) & BMR generation

- Shelf-life/expiration support

- FDA 21 CFR part 11 compliance

Business Benefits of ERP for Pharma Manufacturing Industry

The benefits of implementing an ERP for pharma industry, specifically designed to meet FDA, FSSAI and TGA requirements, are vast:

- Compliance with Regulatory Standards: Meeting FDA, FSSAI and TGA requirements ensures adherence to stringent regulations, ensuring product safety and legality.

- Cost Reduction with Product Efficacy: The pharma ERP software optimises processes, reducing operational costs while maintaining the efficacy of pharmaceutical products.

- Improved Quality and Consistency: Enhancing quality, consistency, and speed in delivering drugs to the market ensures better customer satisfaction and trust.

- Cost Control and Inventory Management: Reduced waste and efficient inventory management contribute to cost control, improving overall financial efficiency.

- Enhanced Safety and Quality: Ensuring safer products of superior quality at the right price and time is crucial, enhancing consumer trust and brand reputation.

- Efficient Preventive and Corrective Action: Quick and effective response mechanisms for preventive and corrective actions streamline operations and mitigate risks.

- Real-time Batch Monitoring: Enables accurate decision-making through real-time monitoring of batches, enhancing operational efficiency.

- Formula Secrecy Maintenance: Offers ease of maintaining the secrecy of crucial formulas and intellectual property, safeguarding against unauthorised access.

- Rapid Response to Customer Demands: The system's agility allows for quick responses to changing customer demands, boosting customer satisfaction.

- Streamlined Operations for Increased Profits: Smoothening operational processes and enhancing efficiency lead to increased profitability and business growth.

- End-to-End Bi-Directional Traceability: From raw material to finished product, the pharma industry software ensures comprehensive traceability, crucial for quality control and regulatory compliance.

Industry Sectors

Biotechnology

Vaccines

Dietary

API

Veterinary

Nutraceuticals

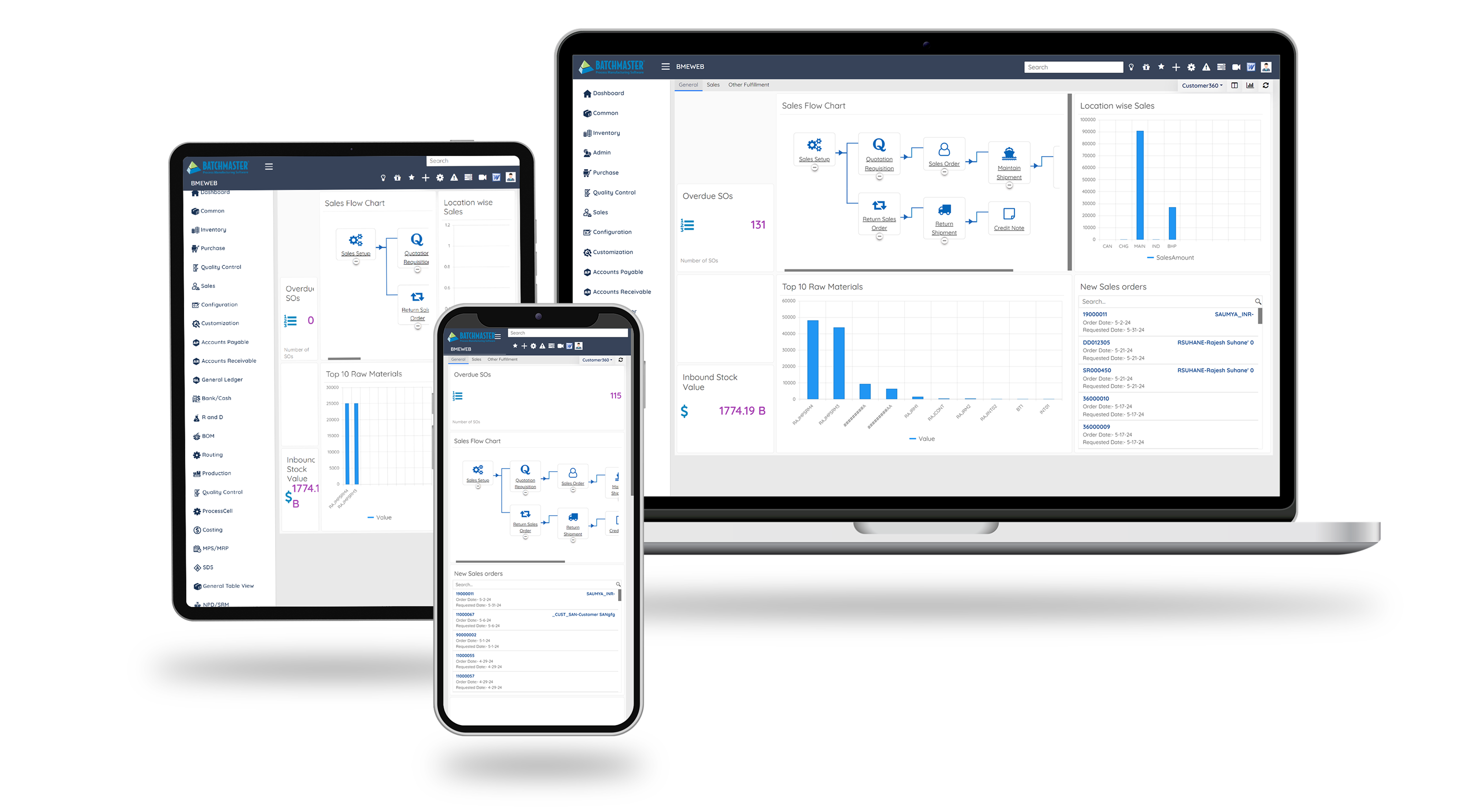

Run Our Manufacturing ERP With Your Existing Financials

Upgrade to our ERP without missing a beat in your financial and accounting routines. BatchMaster ERP offers seamless integration with Tally,QuickBooks Sage 50/100/200/300,SAP Business One and other popular systems, ensuring a smooth transition.

Web/Cloud Deployment Available

Give your small, mid-size, or large-scale businesses the power of our ‘Cloud ERP’ solutions, and enjoy the benefits of leveraging the cloud.

Looking To Find the Best Solution for Your Business?

Allow our expert team of solution consultants to review your business operations so that they can offer you the best-possible solution, either on premise or in the cloud, to meet all your industry-specific needs