Manufacturing is a method of processing raw materials to make products for consumer usage. These products can be classified into many categories and industries based on the type of finished good.

So, before knowing the difference between the terms – discrete and process manufacturing, let’s first understand the concept.

And start with the definitions of these terms.

What is Discrete Manufacturing?

Manufacturing complex products in low volumes with the help of individually counted units is called discrete manufacturing.

Here each piece of the product can be identified and the product can be assembled and disassembled.

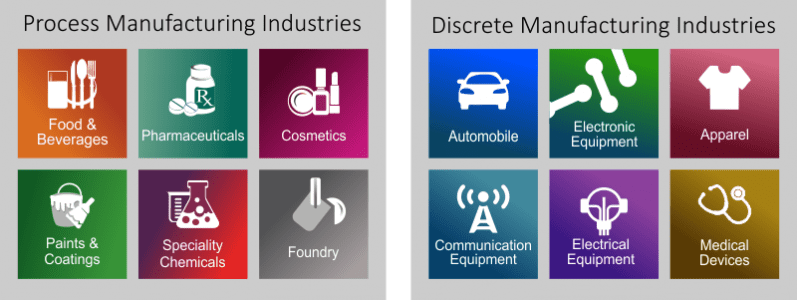

Example – Automobiles, Electronics, Apparels, Machines & Devices etc.

This method uses Bills of Materials (BOMs) and assembles components along an assembly line. In view of that, it includes make-to-stock, make-to-order, and assemble to order production.

What is Process Manufacturing?

To mix, process and combine raw materials to manufacture products in bulk quantities using a fixed formula or recipe is called process manufacturing.

This results in chemical and or thermal conversions. It means that goods are generally produced in the forms of liquid, solid, gel, powder etc.

They are measured in kilograms, tons, liters, gallons and so on.

In case of process manufacturing, the raw materials can’t be taken out from the finished products once manufacturing is complete.

Industries that use process manufacturing include Foods & Beverages, Pharmaceuticals, Paints & Coatings, Chemicals, Cosmetics, Personal Care etc.

How Discrete Manufacturing is Different from Process Manufacturing?

| Discrete Manufacturing | Process Manufacturing |

| Products are comprised of components that can be touched, and counted. | Products are manufactured using formulas or recipes |

| Parts can be broken down & disposed off or recycled after production | Products cannot be broken down back into raw materials |

| Uses Bills-of-Material | Uses formulas or recipes |

| Assembles in a linear or routing way | Blends in a batch |

| Involves joining, attaching, fixing, assembling etc. | Involves grinding, boiling, mixing, churning, etc. |

| Doesn’t involves change of volume or density | Volume, density, mass, physical properties all get changed here |

Products that explain these terms better-

Manufacturing a Car, bicycle, Taps, Mobile Phones, etc, is discrete manufacturing, Whereas producing Tomato Ketchup, Shampoos, Paints, Lubricants, Juices, etc., is process manufacturing.

Some process & discrete manufacturing vertical markets

Both discrete and process manufacturing are as different as cheese and chalk.

Their processes, requirements, regulatory compliances, terminologies, etc, all differ from each other.

Using an ERP solution for process manufacturing that is basically built for Discrete is not at all a good idea.

Manufacturers should opt for an ERP software that is built specifically for their manufacturing type and works the way they work.

This will reduce the implementation time, cost and the need for customization.

BatchMaster Software Pvt. Ltd., is one company that provides unique ERP solutions for both these manufacturing types.

BatchMaster ERP

These ERP software solutions have all necessary tools essential for manufactures to compete successfully in the marketplace and to maximize profits.

BatchMaster ERP is an IT solution that offers formula/recipe-based manufacturer’s assistance for all critical processes like:

- Product development

- Procurement

- Production

- Quality

- Packaging

- Costing

- Compliance

- Sales

- Accounting

- Warehousing, etc.

With 30+ years of experience, it helps manufacturers manage their supply chain operations, reduce wastage, bring down costs, increase profits, stay compliant and manage safety to keep their customers happy and satisfied. Write to us at sales@batchmaster.com to know more.

OptiPro ERP

OptiPro ERP with SAP Business One is a budget-friendly and trustable ERP solution for small to mid-sized discrete manufacturers and distributors.

It provides financial management, supply chain management, CRM, and industry-specific solutions in one single system.

OptiPro ERP gives you the basis to scale and compete, without any struggle and additional cost. Visit www.optiproerp.com for more details.