Food Enterprise Resource Planning Software

Leading BatchMaster ERP for Food & Beverage – Streamline Production, Maintain Quality, and Maximise Growth Potential

Why Food Manufacturers Trust BatchMaster: Leading Food Industry ERP

The food manufacturing industry faces numerous challenges, including fluctuating consumer demand, complex supply chain management, stringent regulatory compliance, and the need for continuous innovation.

BatchMaster food manufacturing ERP is designed to help you overcome these challenges, enabling your food manufacturing business to streamline operations from recipe development to market-ready products.

By integrating essential processes, BatchMaster food manufacturing software helps you maintain consistency in product quality, keep pace with changing consumer preferences, and meet industry standards such as food safety regulations and labeling requirements. With this solution, your business can operate more efficiently, minimize waste, and stay ahead in a competitive market.

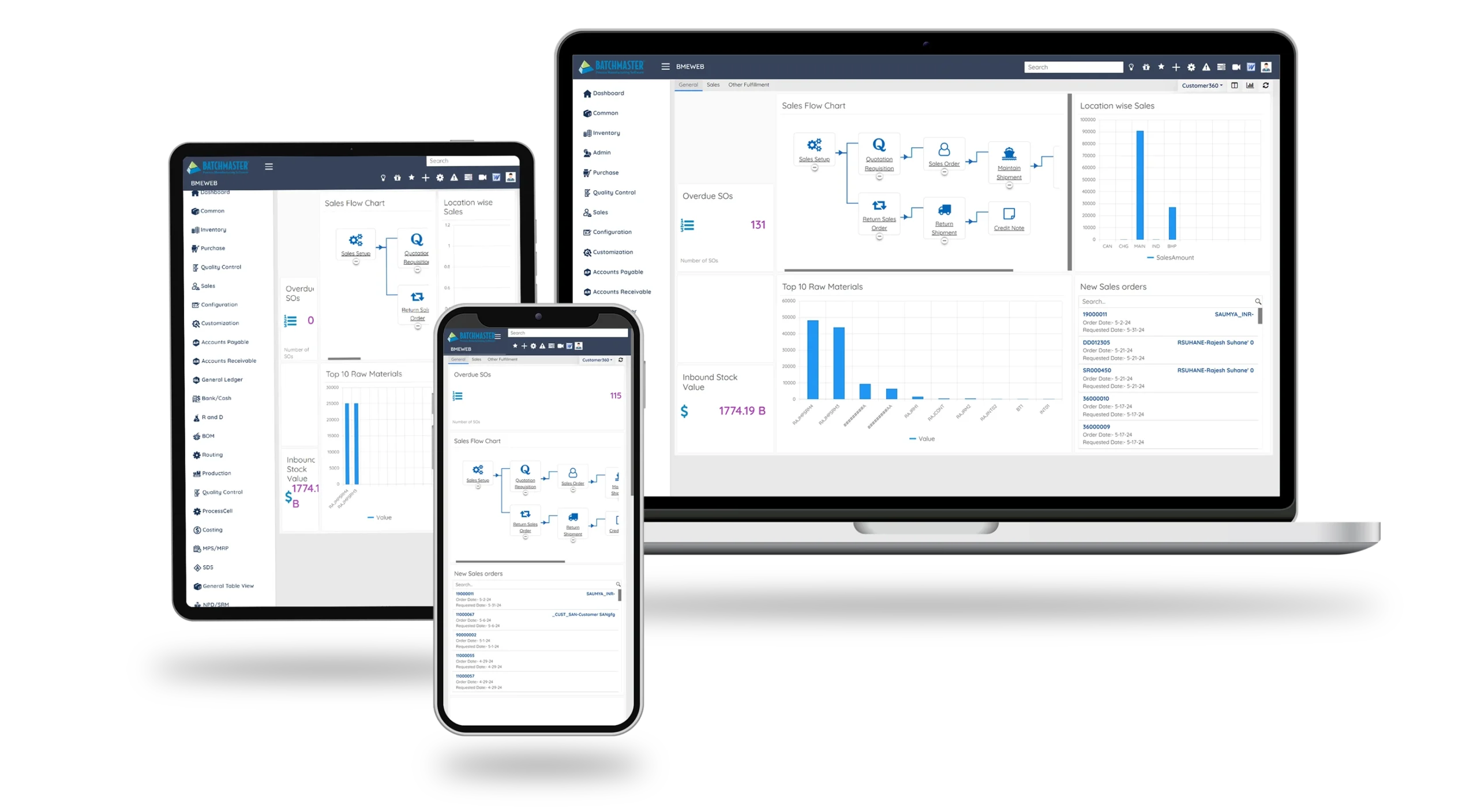

With BatchMaster Food ERP, you can:

- Streamline procurement, inventory, production, quality, costing, and compliance.

- Access real-time insights via customizable dashboards and reports.

- Integrate with financial systems like SAP Business One, QuickBooks, Sage 50/100/200/300, and Tally.ERP 9

Best Food ERP Software for Manufacturing Excellence - Schedule Your Free Demo Now!

Food Industry

How Food Manufacturing System Transforms Operations in the Food and Beverage Sector?

Food production ERP provides manufacturers with a competitive edge by streamlining key processes:

- Recipe Management - Our ERP for food processing streamlines Formula/Recipe Management by enabling you to control access, create secure versions, perform cost calculations, and compare variations seamlessly—an essential capability in any advanced ERP for food operations.

- Cycle Count – Minimize discrepancies between system data and physical inventory. With real-time insights from ERP in food inventory management, businesses can resolve issues faster and maintain operational accuracy.

- Batch Resizing – Optimize raw material usage by adjusting batch sizes on the fly. This feature in ERP for food ensures continuous production and reduced waste, enhancing manufacturing agility.

- Labelling and Traceability – Enable precise nutritional labeling and leverage our visual bi-directional traceability tools. Generate FDA-compliant reports effortlessly—an essential compliance asset in any modern ERP for food processing system.

- Inventory Optimization – Improve stock control using industry-standard methods like FIFO and LIFO. ERP in food manufacturing delivers accuracy and reduces overhead by integrating smart inventory logic.

- SuperBatch – Launch intermediate and final goods in a single run. With this innovative feature, ERP for food manufacturers can dramatically increase throughput and streamline operations end-to-end.

Solutions for Diverse Industries

Transform Your Food Manufacturing Business with BatchMaster ERP

Unlock Predictive Insights, Drive Success, and Achieve Amazing Results!

Business Benefits of ERP Software for Food Manufacturing

Food ERP deliver a host of benefits to food & beverage manufacturers. Check some of them out below:

Manufacture products confidently in line with current market trends.

Tailor-made food processing software allows quicker and more cost-effective product introductions compared to competitors.

Ensure absolute compliance with food safety regulations, enhancing consumer trust.

Reduce wastage, optimize material utilization, and efficiently manage inventory, leading to cost control.

Deliver safe, high-quality products at the right price and right time, enhancing customer satisfaction and loyalty.

Use ERP for food processing industry to gain customer loyalty and promote repeat business.

Achieve end-to-end bi-directional traceability, from raw materials to finished products, enabling effective recalls and quality control.

Improve operational efficiency in the manufacturing process, ensuring smoother workflows and reduced downtime.

BatchMaster ERP in food allows for sales order forecasting and efficient conversion of orders into production plans.

Maintain complete control of your business by accessing real-time data on production, sales, and distribution.

BatchMaster ERP in food allows for sales order forecasting and efficient conversion of orders into production plans.

Must-Have ERP Modules for Food Manufacturing Industry

Key Features of ERP for Food and Beverage Industry

BatchMaster ERP for food industry designed to meet FDA and FSSAI requirements.

- Recipe and Formula Management

- Material and Package Costing

- Bi-directional Lot Traceability and Lot Recall

- Allergen Management

- Master Production Scheduling (MPS)

- Material Requirement Planning (MRP)

- Quality Assurance (QA)

- Quality Control (QC)

- Supplier/ Vendor Management

- Shelf-life determination

- Inspection Planning and Inspection Schedule

- Adverse Event and Complaint Reporting

- Supports seasonal requirements

- Multiple packaging

- Unit-of-measurement

- Lot Strength

- Catch Weight

- Nutritional Labelling

- Halal and Kosher Management

- Ingredient statement and report

- Corrective Action Preventive Action (CAPA)

- Non-Conformance (NC)

- Hazard Analysis and Critical Control Point (HACCP)

See BatchMaster ERP in Action – Book Your Free Demo Now

See how BatchMaster ERP streamlines compliance, enhances workflows, and drives faster, smarter food operations.

Frequently Asked Questions

BatchMaster Food ERP is an integrated software solution designed specifically for the food and beverage industry. It provides a centralised platform to manage, digitise and streamline all core business operations, from initial recipe development and raw material procurement to manufacturing, quality assurance, compliance, and final product distribution.

The system includes food-safety and compliance capabilities like e-Signature, bi-directional Traceability, Record Keeping, Audit Trail, FDA Reports, inventory movement based on QC statuses, Labels, etc., to meet FDA and FSSAI requirements, with integrated tools supporting FSMA/HACCP programs, bioterrorism-related mandates, and GMP practices for regulated food operations.

Yes, BatchMaster ERP provides complete end-to-end lot traceability.

It allows forward tracking—from vendor to customer—as well as backward tracking—from customer to vendor.

This dual traceability ensures faster recalls, accurate investigations, stronger compliance, and total supply chain visibility.

Recipe and formula management with versioning, workflow approvals, cost roll-ups, scaling, substitutions for seasonality or health variants, and integration with Genesis database, nutritional property analysis, formula comparison, etc., support consistent production and rapid innovation.

BatchMaster emphasizes continuous product updates to keep pace with changing regulations and practices across regions, and supports frameworks like FDA, FSSAI, FSMA, GHS, and EPA where applicable.

Looking To Find Best Solution for Your Business?

Allow our expert team of solution consultants to review your business operations so that they can offer you the best-possible solution, either on premise or in the cloud, to meet all your industry-specific needs