ERP For Tea Manufacturing Industry

ERP for Tea Industry: A Recipe for Success

“The spirit of the tea beverage is one of peace, comfort, and refinement.”

“A steaming cup of tea with its soothing aroma entices everyone. From the streets of India to the serene gardens of Japan, this beverage has captured people from all walks of life. Besides its popularity, the journey of bringing tea into the market isn’t that easy.

It involves numerous intricate processes that require expertise and precision during execution. Thus, no other solution than adopting an ERP for Tea industry looks equally capable and effective for this. Explore how an ERP does this.”

Introduction- The History of Tea

Tea, an ancient beverage with origins dating back to 2737 BC in China, has experienced widespread popularity throughout the ages. A long-standing story tells that a Chinese Emperor Shen Nung discovered the tea unknowingly. It was when leaves fell into boiling water, creating a delightful mixture.

It doesn’t matter whether this tale holds any proof or not. But there is no denying that right after its origin the tea rapidly became a staple item in Asian culture.

Today, tea cultivation spans the globe, primarily concentrated in Asia and Africa, but commercially produced by over 60 countries worldwide.

According to statistical data from statista.com, global tea consumption reached approximately 6.7 billion kilograms in 2022, projected to rise to 7.4 billion kilograms by 2025.

This remarkable growth is because of the increasing popularity of tea among all age groups. Its diverse Flavors attract them, and they perceive it to have health benefits too.

Moreover, in response to growing health concerns, the tea market has evolved significantly, expanding to encompass a wide array of varieties. Tea companies have also started developing teas with added nutritional elements.

This includes black tea, green tea, specialty tea, and other unique blends, catering to the discerning tastes of tea enthusiasts.

This further enhances tea’s appeal both as a beverage and a medicinal remedy. Its popularity will continue to surge across the world. Experts project a growth rate of 6.1% for the tea industry in the coming years.

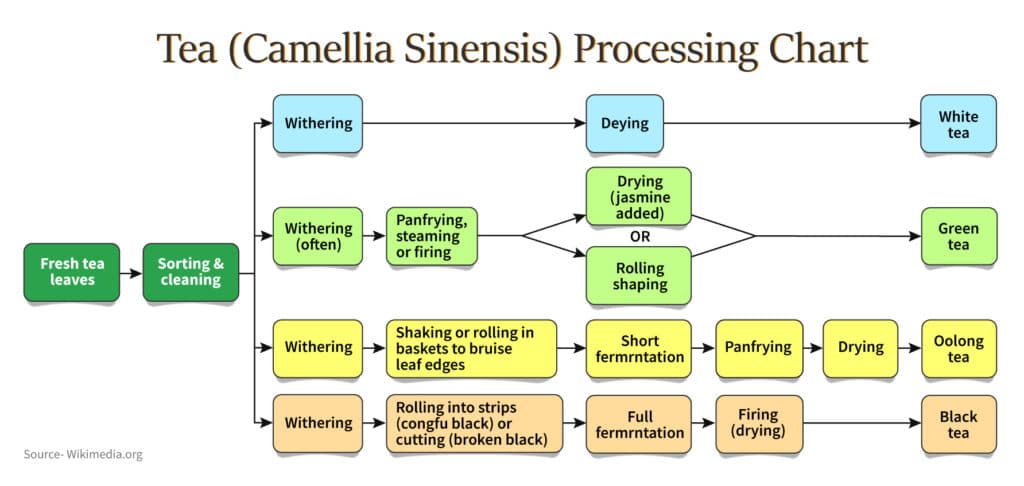

Processes Involved in Tea Manufacturing

Renowned for its refreshing qualities and ease of preparation for consumers, tea manufacturing isn't easy. The journey of tea from farm to table demands meticulous efforts from manufacturers.

The process starts at the tea farms. Here the delicate tea plants are nurtured and cultivated under specific climatic conditions. Followed by it is a meticulous process that encompasses a series of crucial steps that ultimately transforms the leaves into the tea that we enjoy.

The processes are

1. Picking

2. Withering

3. Rolling

4. Roll Breaking

5. Fermentation

6. Drying

7. Sifting/Grading

8. Tasting & Evaluating

Each step plays a crucial role in producing the favour, aroma, and overall characteristics of the final product. Thus, it becomes necessary for the manufacturers to perform every task with utmost precision.

But the story doesn’t end here. In the midst of all this, there are many challenges that the manufacturers have to face. Let us delve into the details of these challenges.

Challenges Tea Manufacturers Face

The tea industry is a dynamic and ever-evolving landscape. This is due to the growing demand for high-quality and innovative tea products among consumers. Due to this, tea manufacturers find themselves at the forefront of this trend, facing a myriad of opportunities and challenges too.

At one end, manufacturers can benefit themselves with the opportunity to explore new blends, flavours, and packaging options. This helps them stay ahead of the curve and capture the attention of tea enthusiasts.

While, on the other end, numerous challenges restrict manufacturers from unlocking their complete potential and achieving the desired results. One such challenge is the need to maintain the consistent supply of high-quality tea leaves.

The reason behind this are the factors that cause abrupt climatic changes. Increasing global warming and unusual rainfall directly affect the yield and quality of the tea crops. According to a study, for every 100 kilograms of the tea leaves, only about 25 Kilogram leaves are suitable for production.

Such scenario disrupts the supply chain and ultimately manufacturers fail to fulfil the major requirement of quantity. The pressure of successfully navigating through this situation grows big when another challenge of maintaining strict quality standards enters.

Additionally, the labour-intensive nature of the tea industry makes the process more complex for manufacturers. Apart from the process of ploughing and planting seeds, tea crops require around a year of maintenance. This includes the processes that are exclusively done by hands such as weeding, mulching, pruning, and trimming.

Other processes that demand labour force are steaming, drying, rolling, roll breaking, grading, and packaging. All these processes require adequate quantity of efficient labour force. Shortage of labour in any of these processes will directly result in production stoppage and lost opportunities.

Furthermore, problems like poor management, old tea bushes, and infrastructure inefficiencies make it harder for manufacturers.

Considering all these challenges manufacturers must take some result-oriented actions that could help them navigate successfully. Though we can't alter situations like changing climatic conditions and fluctuating weather patterns as per our needs. But streamlining supply chain, maintaining strong relationships with the suppliers, managing compliance, and meeting quality standards are the factors that can be controlled and managed.

But how? Is there any such technology by adopting which manufacturers can easily overcome all these challenges. Certainly, that’s an Enterprise Resource Planning System (ERP) built specifically for Tea Manufacturers.

ERP For Tea Industry- The Scoop of Success

The fundamental reason behind organizations experiencing less productivity and reduced profit margins is the approach they work with. These organizations still rely on the paper-based processes that are highly inefficient and error-prone. This reduces their productivity significantly.

For all such reasons ERP becomes the tool for success. Enterprise Resource Planning or say ERP for tea industry play a crucial role by providing a comprehensive support to tea manufacturers.

Right from automating and streamlining the various aspects of the production process, ERP offers a range of benefits to tea manufacturers.

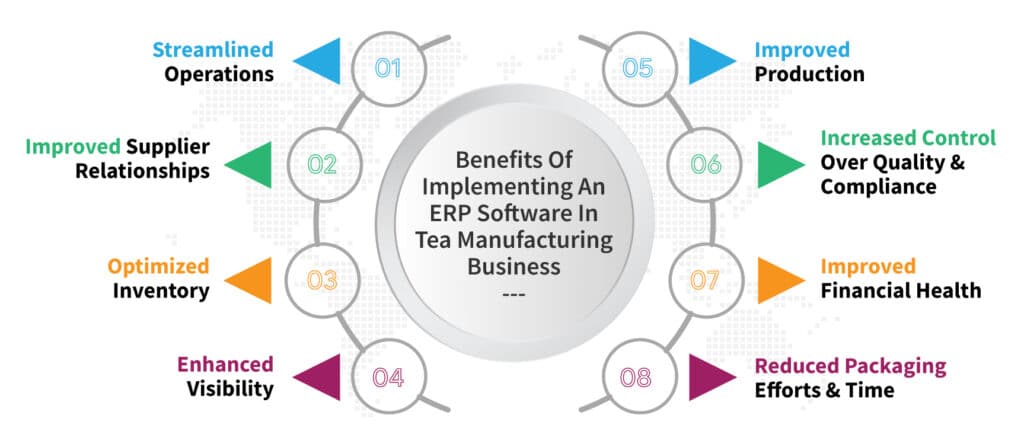

How ERP Benefits the Tea Industry- The Tea-Twist-

1. Streamlined Operations

ERP for tea industry provides a common platform that integrates all the processes. Right from procurement, production, inventory, to packaging, sales, and distribution everything remains on the same page. This integration streamlines management, reduces errors, and improves operational efficiency.

Furthermore, the ERP incorporates unmatchable level of automation into the processes, reducing the dependency on labours. This allows the labour workforce to focus on other operations.Furthermore, the ERP incorporates unmatchable level of automation into the processes, reducing the dependency on labours. This allows the labour workforce to focus on other operations.

2. Improved Supplier Relationships

Discarded tea leaves show the sign of over burn or water damage. Thus, it’s extremely crucial to ensure your supplier provides high-quality of material always.

With an ERP, manufacturers get a centralized platform to manage and communicate effectively with the suppliers. Through this, manufacturers can easily share purchase orders, delivery schedules, and quality requirements, reducing misunderstanding, and minimizing the chances of poor quality.

It even allows selecting the best vendor based on their performance on various parameters like, quality, lead time, cost, certifications, etc.

3. Optimized Inventory

It’s an incredible task to manage right amount of raw material, at the right place, and at the right time. To make this possible, ERP integrates all the departments and offers data sharing capabilities. This helps the purchasing department stay in sync with production and maintain optimal inventory levels, avoiding overstock or understock.

4. Enhanced Visibility

Food and beverage ERP software provides complete visibility throughout the supply chain. It allows manufacturers to record and track every detail of each tea lot upwards and downwards along the supply chain.

Even when any quality issue occurs, the lot traceability feature enables quick identification and isolation of the defected tea lots. This lets tea manufacturers rapidly trace the origin and production details of such lots, reducing their impact on people and brand itself.

5. Improved Production

Producing tea according to the market demands requires smooth execution of production processes. The ERP production module for tea industry efficiently handles all tasks of the production process and enhances the production efficiency significantly.

It plans and executes everything from materials to labour and machinery, considering the demand, supply, and resources. Thereby optimizing the production capacity and profitability.

6. Increased Control over Quality and Compliance

Delivering supreme quality tea is essential for having a good hold over the tea market. However, ensuring quality at every step seems like a significant challenge.

An ERP software for tea industry eases this complex task of ensuring quality. By defining and enforcing standard operating procedures (SOPs), conducting quality inspections, and applying QC tests it helps manufacturers uphold quality at all important stages- procurement, in inventory, during production and while dispatching.

Additionally, it also prevents manufacturers from hefty legal fines by ensuring they adhere to the required compliance standards every time.

7. Improved Financial Health

Managing finances is the backbone of every business. Using manual process for calculations and tracking bills, payments, and receipts would lead to errors.

But, with an ERP you can automate all this. The system manages everything digitally including accounting, budgeting, and reporting. This helps tea manufacturers track costs, manage expenses, and analyse profitability.

8. Reduced Packaging Efforts & Time

Relying on traditional packaging methods acts as a hindrance in the cycle of demand and supply. Hence, tea businesses need a technology that can optimize the packaging process and ensure increased efficiency.

By adopting a right ERP, you can achieve this goal. This technologically advanced system allows supports multiple packaging and also generates labels in the standard formats with all the precision required.

How BatchMaster can be the - Helping Hand

By adopting a right ERP, you can achieve this goal. This technologically advanced system allows supports multiple packaging and also generates labels in the standard formats with all the precision required.

But it's possible with a robust software solution like BatchMaster ERP. It automates and streamlines every operation of tea manufacturing making them like a walk in the park. With improved processes and quality, the manufacturers get an edge over their competitors and thus success and profitability. Feel free to contact our team of experts for further information.