ERP for Dietary Supplements

Today, dietary supplements have become increasingly popular due to increased consciousness about health among people. Consequently, the dietary supplements industry has experienced consistent growth over the past decades.

The primary role of these supplements is to complement an individual's regular diet by providing additional nutrients. Moreover, they are marketed to target specific nutritional deficiencies and contribute to overall health and wellness.

Among the plethora of supplementary products, health experts prominently laud vitamins, minerals, herbs, amino acids, and enzymes. These products are available in diverse forms, including capsules, powders, tablets, liquids, and gummies.

While dietary supplements undoubtedly enhance individuals' well-being, the process of manufacturing these products presents a significant challenge for manufacturers. Compared to other product types, the manufacturing of dietary supplements stands out as a unique task to undertake.

Would you like to learn more about our Dietary Supplement ERP?

Pharmaceutical Industry

What Makes The Process Of Manufacturing Dietary Supplements Unique?

In the realm of dietary supplements, multiple nutrients work synergistically, when combined in proper proportions. The effectiveness of one nutrient is enhanced or dependent on the presence of another. That’s why calibration holds significant importance during the manufacturing of dietary supplements.

Apart from carefully formulating these ingredients, various intricate operations stir up trouble for manufacturers. These operations encompass compliance management, quality control, packaging, labelling, storage, etc.

In order to effectively address these distinct challenges while simultaneously maintaining competitiveness, the adoption of a uniquely tailored solution, such as an ERP software for dietary supplements becomes a necessity for manufacturers.

Why Dietary Supplement Manufacturers Need ERP?

Many Dietary Supplements Manufacturers still rely on outdated legacy systems or paper-based and people-intensive processes to document every step of production. However, due to this reliance, manufacturers are finding it increasingly difficult to comply with stringent FDA regulatory mandates and follow Current Goods Manufacturing Processes.

Moreover, management of thousands of formulas, each with numerous versions, presents a daunting task. The mishandling of even a single formula could disrupt the entire formulation process, leading to resource wastage or production interruptions.

Furthermore, the significance of tasks such as demand planning and production scheduling cannot be understated. These tasks encompass various stages, including mixing, encapsulating, compressing, polishing, and packaging, each requiring meticulous attention.

That’s precisely why adopting an automated manufacturing software like dietary supplement ERP is the uncompromising need of the manufacturers operating in this industry.

How ERP Will Help Solve These Challenges?

BatchMaster ERP for Dietary Supplements is one such ERP software for dietary supplement manufacturing that understands the unique needs of this specialized sector and helps supplements manufacturers in ensuring the well-being of their businesses. This business management tool automates and efficiently manages the core business processes enhancing process efficiency and reducing operating costs significantly.

Right from planning, production, quality, costing, traceability, to compliance, packaging, and delivery, BatchMaster ERP for Dietary Supplements ensures smooth and streamlined execution of all the manufacturing operations.

This helps them ensure attainment of requisite production benchmarks, both in terms of quality and quantity, match their deadlines, and stay ahead in the competition always.

Key Features Of BatchMaster ERP For Dietary Supplements

- Supports different production types like- capsules, syrups, gels, gummies, etc.

- Nutritional Labeling and Supplement Fact sheet generation in standard formats

- What-if analysis to achieve targeted nutritional properties in formula/recipes

- Multiple Packaging of same formula

- Separate costing of formula and packaging

- Master Batch and Batch Manufacturing Record Management

- Inventory Management with material characteristics such as lot potency, lot characteristics, lot statuses, expiration management with stability testing, etc.

- Raw Material plus Production Planning and Procurement

- Complete Sales & Procurement Management

- Quarantine Management

- Bi-Directional Lot Traceability

- Adherence to FDA 21 CFR Part 111 compliance

- Supplier/Vendor management & qualification

- Quality Control Operations implemented at all stages of supply chain with action plan.

- Efficient handling of complaints, returns, and recalls

- Co-Product and By-Product Management

- Electronic execution of SOPs by inspection checklist

Benefits Of BatchMaster ERP For Health Supplements

- Quickly adjusts formulas to meet their label claims

- Ensures immediate use of substitute in any formula

- Rapidly brings new products to market

- Prevents legal fines and penalties

- Helps to take accurate business decisions

- Controls costs by reducing wastage

- Maintains formula secrecy

- Scalable to meet ever-changing compliance mandates

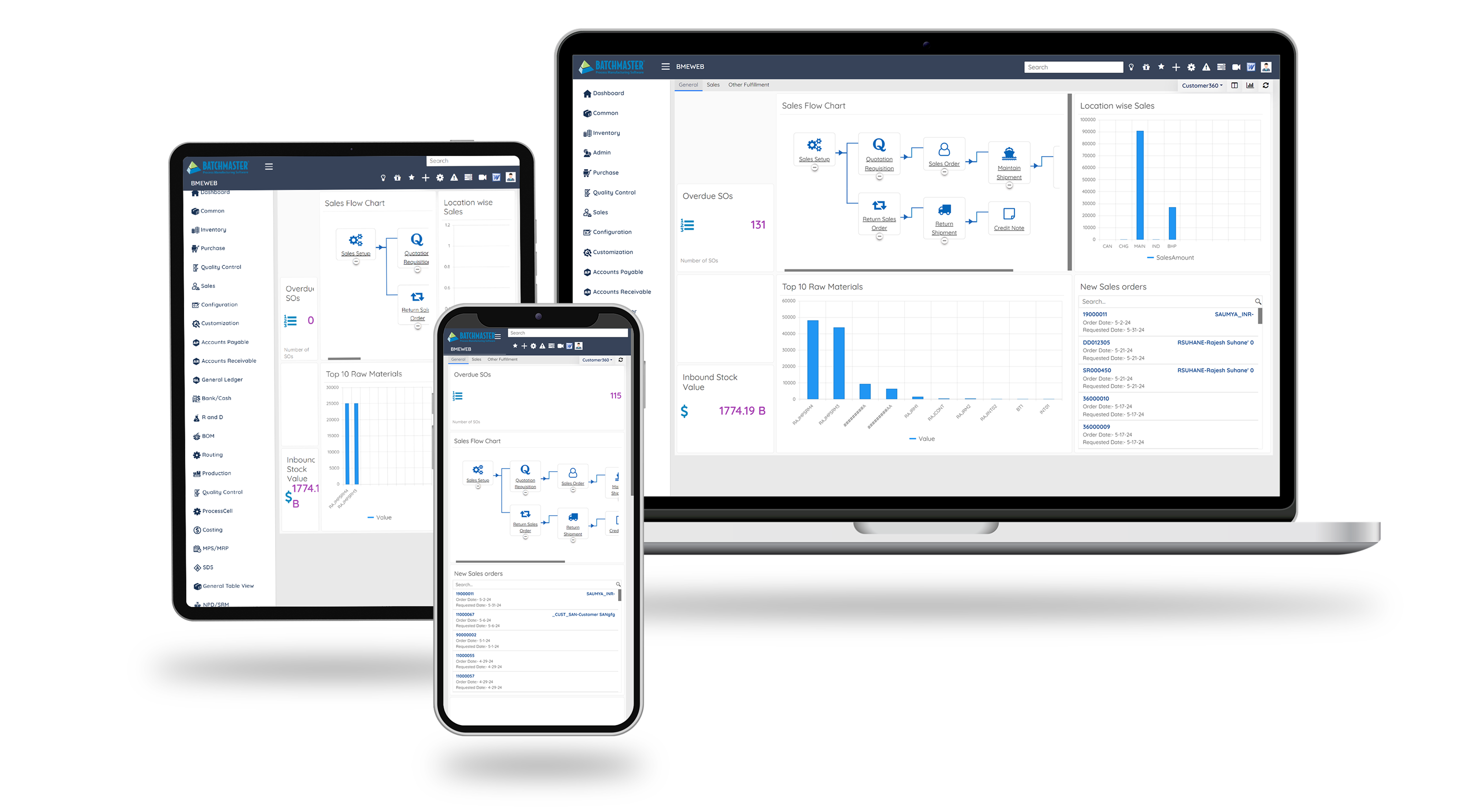

Run Our Manufacturing ERP With Your Existing Financials

Upgrade to our ERP without missing a beat in your financial and accounting routines. BatchMaster ERP offers seamless integration with Tally, QuickBooks, Sage 50/100/200/300, SAP Business One and other popular systems, ensuring a smooth transition.

Web/Cloud Deployment Available

Give your small, mid-size, or large-scale businesses the power of our ‘Cloud ERP’ solutions, and enjoy the benefits of leveraging the cloud.

Looking To Find Best Solution for Your Business?

Allow our expert team of solution consultants to review your business operations so that they can offer you the best-possible solution, either on premise or in the cloud, to meet all your industry-specific needs