Overview-

Implementing ERP software in 2025 is no longer just adopting a technology, it’s about transforming business operations to align with a rapidly evolving business landscape. Ensuring a successful and effective ERP deployment requires businesses to adopt those best practices that minimize disruptions and maximize returns on investments.

According to Gartner’s report, around 55%-75% of ERP projects fail due to extended timelines or budget or fall short in fulfilling the basic purpose of manufacturing organizations.

A failed ERP implementation results in a huge loss for any organization, as it impacts the company on crucial fronts such as costs, productivity, and revenue. On the contrary, a successful ERP implementation benefits an organization in many ways including fulfilment of business requirements, adherence to compliance and standards, productivity & efficiency improvement, etc.

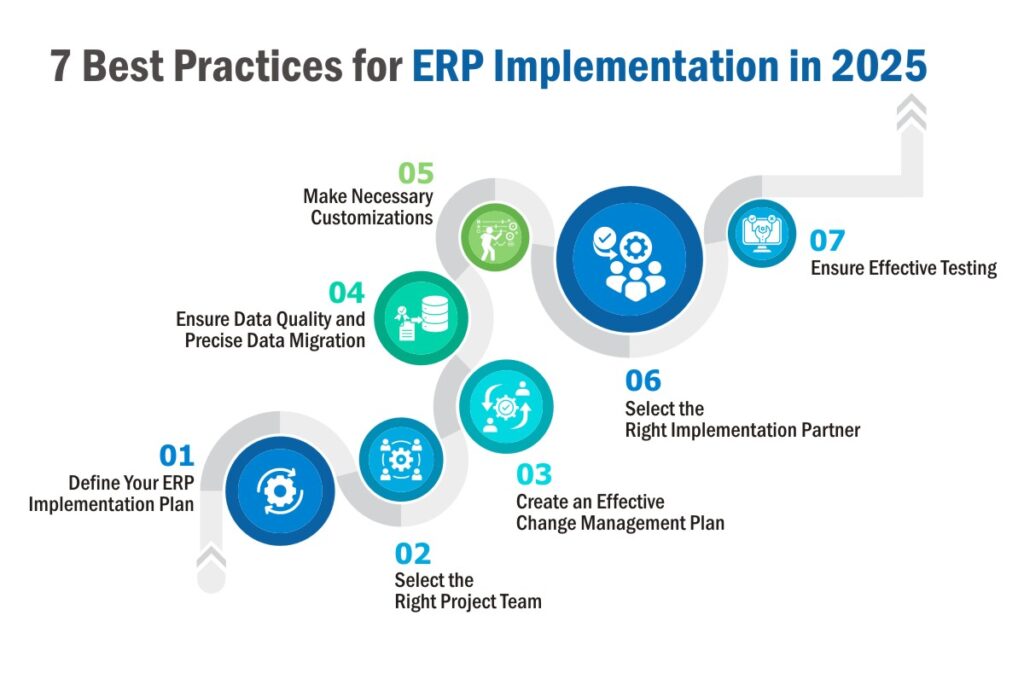

This blog will uncover those seven best practices every manufacturing organization should adopt to ensure a successful ERP implementation–

1. Craft Your ERP Implementation Plan-

To prevent yourself from being a part of the “failed ERP implementation” pack, start with performing a detailed analysis of your organization’s current processes, pain points, objectives, and future goals.

Also, a plan or workflow should be drawn mentioning each stage including-

- Migrating data from the existing setup

- Creating an implementation roadmap

- Estimating the cost and allotting a budget to the implementation process.

- Setting up a real timeline for project completion.

- Performing post-implementation testing in a sandbox environment.

- Creating a training program for end-users, explaining the procedure to use ERP effectively.

Planning this way will help you break your ERP implementation program into manageable bits, and tick mark the tasks from to-do to done.

2. Select the Ideal Project Team-

Choosing the most suitable candidate for a role proves advantageous, as this minimizes the likelihood of errors and delays in task execution. Similarly, during an ERP implementation process, choosing the right team ensures success.

- Appoint a project manager who will steer the project by providing direction and regular updates.

- Employ an application analyst to manage the data migration process.

- Enrol QA test engineers to evaluate the system post-installation to identify bugs and errors, if any.

- Change management experts that are responsible for executing the change and communicating across the organization, why this change is happening.

3. Create an Effective Change Management Plan-

Change management is the process of planning and implementing changes successfully within the organization. In this case, the change relates to switching to a new ERP platform.

Accepting a change is a psychological factor and assuming that people will accept your plans, can be a step towards ERP implementation failure.

An effective change management plan should be in place and must involve-

- Conducting a thorough analysis of all stakeholders involved in ERP implementation.

- Communicating the reasons for this change, the benefits ERP will bring, and the expected impact on day-to-day operations.

- Developing user training programs tailored specifically to train employees comprehensively about ERP.

- Performing regular evaluation programs to assess the effectiveness of the change management plan.

4. Ensure Data Quality and Precise Data Migration-

An ERP implementation process is a perfect opportunity to refine all the organizational data and put it into a streamlined order. This is because, uncleaned, messy, and improper data might lead to poor decision-making, costing you millions.

- Begin by assessing your existing data thoroughly, identifying inaccuracies, inconsistencies, and redundancies.

- Figure out the requirements of the new ERP system such as supported data formats, standardized units, etc., and start transforming data accordingly.

- Instead of going in a go, divide the data migration process into manageable segments. This will facilitate easy validation, and quicker issue resolution, if any, and also minimize the impact of potential errors.

- Involve end-users in the data migration process to ensure the accuracy of the migrated data.

- Ensure strong collaboration between the data migration team involving IT professionals, data analysts, and end-users.

5. Make Necessary Customizations-

Customizations help manufacturers tailor the ERP software to meet their specific business needs. This enhances the system’s functionality, benefiting companies on the productivity front.

However, it is necessary to incorporate only those customizations that are really needed, as unnecessary customizations increase the time, cost, and complexity of the implementation process. For this, a framework should be followed-

- Conduct a comprehensive needs analysis, identifying those specific requirements.

- Evaluate if the identified needs can be fulfilled with the selected ERP system.

- Assess the potential impact of the customizations on the system’s overall performance.

- Conduct a cost-benefit analysis, justifying the needed investment in customizations.

6. Select the Right Implementation Partner-

When selecting an ERP, organizations need to have a specific criterion in mind based on their requirements.

A general criterion involves considering factors such as software’s cost-effectiveness, scalability, user-friendliness, customization capabilities, and its overall ability to fulfil organizational needs. Based on these considerations, companies must look for an ERP that would be the best fit for their needs.

7. Ensure Effective Testing-

The process of thorough testing helps identify the issues and errors before they impact the entire system. It involves validating ERP’s functionality, its integration with the existing system, and alignment with the business processes.

- Involve end-users in the testing process as this will help you gather valuable feedback regarding its usability from those who will be using it daily.

- Check the system under different scenarios including routine operations and stress conditions, ensuring its reliable working under various circumstances.

- Also, check the system on other crucial fronts like data accuracy and security measures like user-access controls, to ensure the integrity of business information.

Final Thoughts-

No organization would love to experience a chaotic ERP implementation project and remember it as a horror story. After all, nobody wants to lose hundreds of thousands of dollars along with their greatest resource “time.”

While the ERP implementation process appears to be a complicated one, solid planning, proper resource allocation, and perseverance will help you navigate this journey easily. If you are considering adopting an ERP for your manufacturing unit and want to have a streamlined and flawless implementation then, BatchMaster ERP is for you! Contact our team of experts today to know more about it.