Did you know? Cadbury was the first company to associate chocolates with an expression of love through their heart shaped packaging, as early as 1868! This marketing move changed the face of the Confectionery industry forever.

Since then, Confectionery items have been incorporated in birthday, anniversary and festival celebrations along with being on-the-go snacks.

The Confectionery manufacturing industry has a rich history and it has gone through drastic changes in recent years.

Supply chain disruption caused by COVID-19 brought price volatility in the industry’s primary raw materials, cocoa, vanilla and sugar.

Additionally, increasing customer awareness regarding the excess calories in chocolates, candies and gums has forced manufacturers to rethink their product offerings.

With customer preference shifting towards luxury chocolates and manufacturers developing sugar-free and organic Confectionery, the industry is expected to grow at a CAGR of 3.8% over the next 5 years to become a $242.53 billion market.

This growth will be fuelled by the industry’s openness to embrace automation and the application of software like ERP, PLM, MES and QMS in their manufacturing facilities.

ERP – The cocoa to the chocolate businesses

Candies and confections have some of the most complex production procedures and also some of the widest product ranges.

Reworks, mingled lots and complicated ingredient requirements make the manufacturing endeavor all the more challenging.

ERP can shoulder the responsibility of facilitating innovation, bulk ingredient management, allergen management, multiple packaging, quality control, regulatory compliance, end-to-end traceability and a lot more.

A competent Confectionery ERP software has separate modules for all the business functions that are significant to Confectionery manufacturing.

Right from procurement to production, Opportunity tracking to shipment and inventory plus finance to compliance, these modules interact with each other and exchange real-time data on the company’s operations.

This data is saved on a unified database, thus enabling every department to access the same information.

ERP for Confectionery supports industry-specific activities like blending, mixing, heating, cooling, etc. by recording steps of WIP (work-in-progress).

And with the widespread availability of cutting-edge technologies, Confectionery ERP software is now available for every manufacturing organization, irrespective of its size & structure.

It provides complete location-agnostic control over business processes and material movements through various access points including tablets and smartphones.

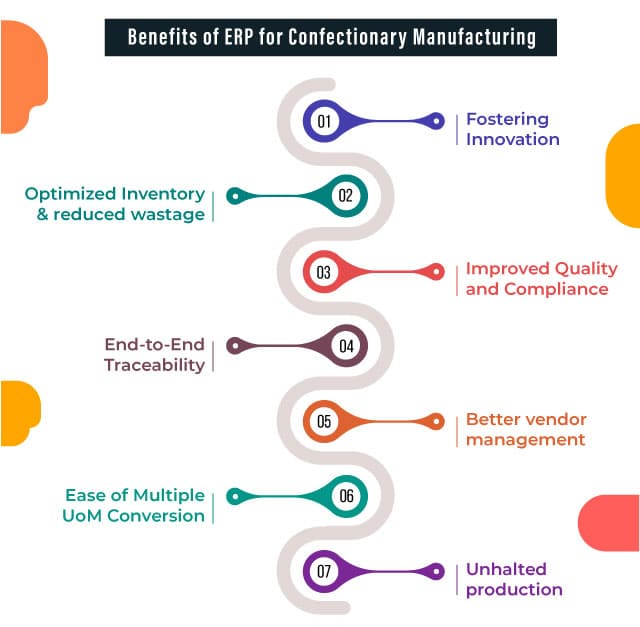

Benefits of ERP for Confectionery

In addition to supporting halal and kosher management with ingredient statement & report, ERP also helps with catch weight management, lot strength and shelf-life determination.

Below are some of the major benefits of ERP software for Confectionery industry:

Better vendor management –

The price of ingredients like sugar, cocoa butter and vanilla essence have gone up significantly in recent times.

ERP allows manufacturers to select the best vendor on the basis of variables like price, quality, lead time, etc. ERP system estimates material requirements in advance, enabling Confectionery manufacturers to buy raw materials when the price is low.

ERP also keeps track of blanket agreements to obtain materials at regular intervals on pre-decided prices, shielding manufacturers from price fluctuations.

Amid the growing demand for novel flavors and exotic Confectionery, manufacturers need to speed up their product development process. ERP accelerates the entire lab-to-loft process with its formula management capabilities.

Faster time-to-market –

ERP issues time-sensitive alerts to stakeholders to expedite formula approvals. With a single click on the ERP system, decision makers can send the formula directly into production.

All these activities collectively result in faster time-to-market and enable manufacturers to capitalize on their first mover’s advantage.

Inventory Planning and Management –

By maintaining a history of goods sold, ERP software can predict the amount of inventory needed to fulfill seasonal/festive requirements.

By assuring that the inventory levels are optimum, it eliminates wastage and reduces inventory carrying costs.

With insights into Available-To-Promise and Probable-Available-Balance, manufacturers know the required material levels and order the extra inventory needed to fulfill orders.

Easier Material Substitution –

The consumer wants to eat healthier, which requires manufacturers to come up with sugar replacements. During innovation, ERP facilitates material substitution even at the last minute, without needing to add them to the inventory module.

ERP presents new calculations according to the replaced material and lets the manufacturer adjust the formula to preserve the consistency and properties of the finished product.

Minimized losses –

ERP tracks and monitors the output at every stage of the production process. By drawing comparisons between expected and actual yields, ERP helps you take appropriate steps when it falls down below the threshold.

Also, materials like liquid chocolate, candy and gum can stick to the surface of the machines, which can result in substantial material losses and also affect the machine’s output.

ERP can schedule regular cleaning and maintenance activities of your machines in order to increase the cumulative throughput.

Quality Enhancement –

Confectionery manufacturers produce a wide range of products at any given time. The short cycle times of these processes can prove to be challenging for product quality.

Right from temperature management to formulation checks and viscosity monitoring to metal detections, the QC module of ERP takes care of every quality issue.

Standard safe practices for toxicological and microbiological elements along with allergens can be specified with the help of ERP software for Confectionery industry.

End-to-End Traceability –

ERP provides granular control in mapping the movement of an ingredient from its entry into the warehouse up to the point of customer delivery and tracing it back from finished goods to material level.

Assigning each lot with a unique identification number lets manufacturers act quickly in case of a product recall.

It saves the company from calling back the entire production output and only act on the problematic lot.

Quality audits can also be made easy, as the location and stage (inventory/WIP/finished goods) of the materials is known at every moment.

Improved Compliance –

Regulatory bodies are constantly updating their guidelines relating to GMO products.

Therefore, ERP helps Confectionery manufacturers stay on top of the latest developments regarding the regulations surrounding their cocoa inventory.

ERP automates the tracking and control of FDA, BRC and IFS regulations with compliance related activities like documentation, planning, reporting, audit, etc.

ERP also simplifies the reporting of non-compliance events to save the company from legislative action.

Calculations in Multiple UoM –

Materials with different UoM (Units of Measure) can be used to produce finished goods. The raw material may be measured in liters (milk for example), while the finished goods might be weighed in grams.

ERP supports the conversion of materials from one unit to the other and even provides mathematical calculations for the same.

These calculations can also be used for scaling the formula in different proportions and preserving product composition.

Scheduling Quarantine Packaging –

In a Confectionery, the separation of allergens and segregation of halal & kosher products has to be done very carefully.

ERP helps manufacturers take all the necessary safety steps to perform controlled packaging in order to separate allergens from your materials.

ERP aids manufacturers to achieve global security standards by setting customized schedules and notifications at the packaging stage.

An ERP software for Confectionery industry can provide information from all business verticals on a unified dashboard. The presentation of information in an understandable format can lead to better decision making, process optimization and performance enhancement.

If you are a Confectionery manufacturer, BatchMaster ERP provides industry-specific solutions to the challenges that you face in your Confectionery business. To get a demo of our ERP product, click here.