Centralized or decentralized manufacturing – the jargons have been there in the conversation among manufacturing conglomerates for quite some time now. For many, the discussion is more in managerial context and for others it is more of convenience.

Nevertheless, in both the cases, the final convergence point is profit and financial matters.

This blog will break down the terms for you, evaluate profits /loss or merits/ demerits of each manufacturing approach and will suggest a software that has its wide role in both cases.

- What is Centralized Manufacturing?

- Advantages of Centralized Manufacturing

- Disadvantages of Centralized Manufacturing

- What is Decentralized Manufacturing?

- Advantages of Decentralized Manufacturing

- Disadvantages of Decentralized Manufacturing

- What are the Differences Between Both Manufacturing?

- How Does BatchMaster ERP Help in Both Manufacturing?

- Conclusion

What is Centralized Manufacturing?

Centralized Manufacturing is manufacturing where all the manufacturing processes are carried out in the same facility, often owned, and operated by an organization.

This manufacturing approach allows both better quality control and oversight of the6g.whole manufacturing process. This manufacturing approach brings down per unit cost of the product due to economies of scale.

The same machinery, labor is used to produce a greater number of products which reduces cost per unit. Centralized manufacturing is observed where manufacturing involves complex or expensive production process.

Advantage of Centralized Manufacturing:

Centralized manufacturing has many advantages like:

- Economies of Scale – With all processes happening at one place, production happens faster, precise and with the same fixed resources which eventually cut down per unit cost.

- Standardization – Since all the processes happen at the same place, all teams follow similar standard guidelines and processes, resulting product standardization.

- Optimum resource utilization – Available resource – be it labor, machines, etc can be optimally utilized.

- Easy supply chain management – Since all production processes occur at a single location, inventory complexity and logistics chaos are handled easily.

- Minimum administrative cost – Centralized manufacturing incur lower administrative cost as there is only one location to manage.

Disadvantage of Centralized Manufacturing:

- Tendency to disruption – Any disruption in facility can hamper production process and disrupt entire production pipeline.

- Higher transportation cost – When manufacturing is done at a single place, it must be transported to various locations for final delivery. This increases transportation cost.

- Less adaptability – A centralized manufacturing is less adaptive to the changing customer demands as tweaking according to area specific demand is not possible. Even minor tweaks in process will attract lot of changes which is generally not an easy task.

- Late response – Market is dynamic, but centralized production is broadly static. Hence, according to the demand, there is always more response time from manufacturing side leading to opportunity loss.

- More inventory cost – Centralized production require high holding of inventories to ensure regular supply of products. This increases inventory cost.

What is Decentralized Manufacturing?

Decentralized manufacturing is manufacturing approach where manufacturing processes are distributed over various locations. With this approach, manufacturers come closer to customers and can cater to their demands locally which reduces transportation cost, time lag between order and delivery.

Advantages of Decentralized Manufacturing:

Decentralized manufacturing has various advantages. Some of which are:

- Flexibility – Decentralized manufacturing can cater to local needs and demands easily. Hence, it is more flexible in approach.

- Less response time – Decentralized manufacturing can respond fast to change in trends and consumer preferences. This fast response time enhances customer tenacity and boosts profits.

- Less transportation cost – Since manufacturing is not centralized, the product is distributed in the market through the nearest facility. This saves fuel cost.

- Lesser vulnerability to disruption – Due to production at various facilities, disruption at one location does not hamper processes at another. This reduces chances of complete breakdown.

- Reduced inventory cost – Decentralized manufacturing require lesser inventory than centralized inventory since it is more affected by local demands, resulting lesser inventory cost.

- Creating more jobs – Local manufacturing offers jobs to many people locally. Hence, it supports local economies and boosts living standard of local people.

Disadvantages of Decentralized Manufacturing:

Decentralized Manufacturing have various disadvantages as well. Here are some of those:

- Higher per unit cost – Sine economies of scale do not apply, per unit production cost is higher.

- Coordination issue – Since production is done at various stages, aligning them all and coordination is tedious. Even a single slip of information can break the chain of production.

- Lesser transparency – Various facilities have isolated working, reducing transparency in the whole eco system. This transparency flaw eventually can cost opportunities, and trust of customers.

- Supply chain disruption – Since production is decentralized, there is no centralized control over supply chain. Lack of alertness at a single junction can disrupt whole supply chain.

- More administrative cost– Decentralized manufacturing require additional resources like labor, machines, facility etc which raise overall administrative costs.

- Higher capital investment – To create infrastructure at each location, decentralized manufacturing requires more capital investment.

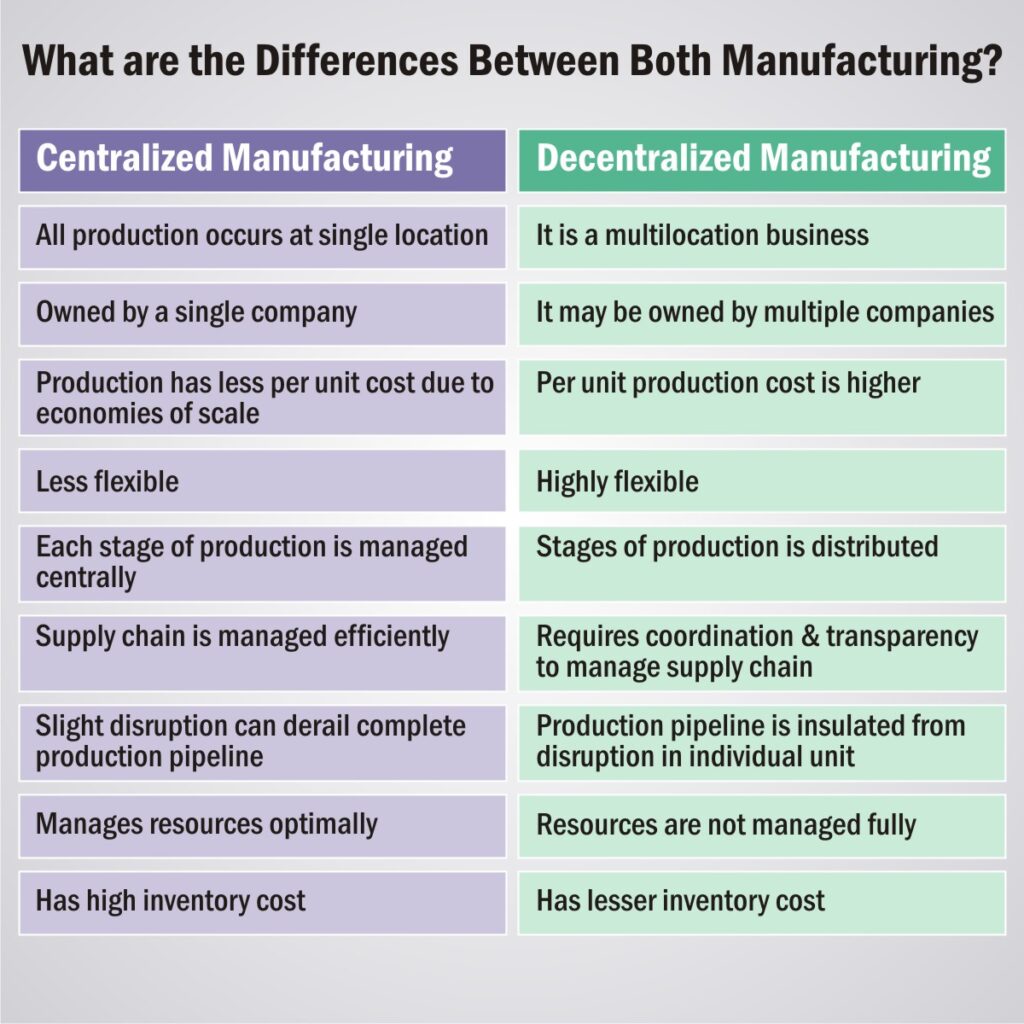

What are the Differences Between both Manufacturing?

How Does BatchMaster ERP Help in Both Manufacturing?

BatchMaster ERP is a trusted ERP for process manufacturing. Being pioneer in formulation, the software streamlines day-to-day functions of your manufacturing unit. Be it centralized or decentralized manufacturing, BatchMaster ERP offers various functionalities. It supports and eases both approaches of manufacturing by:

- Inventory management – BatchMaster ERP allows you to manage various warehouses, including warehouse transfer or warehouse movement. It shows live status of material in hand and adjusts warehouse in and out in real time. It shows ordered quantity and hence enables concerned to take prompt decisions related to inventory. Besides, some inventory needs special attention and have specific storage condition like dairy products or non-veg products. BatchMaster ERP can manage inventory up to bin level to enable inventory micromanagement.

- Production planning – BatchMaster ERP offers meticulous production planning for both manufacturing approaches through MRP/MPS. Well planned production ensures inventory optimization and opportunity grabbing. Besides, it avoids wastage.

- Cost analysis – BatchMaster ERP gives you inventory cost. It helps you to calculate formula cost, and cost of finished goods. While calculating finished good cost, it takes formula cost, packaging cost, labor cost, etc, everything into account. It can help you to decide market viable yet profitable cost and allows to make ‘what-if’ analysis for further cost control.

- Seamless coordination and transparency – BatchMaster ERP offers transparent communication among various departments and facilities. This transparency fosters teamwork builds trust on each department and grabs opportunity in time.

- Integration – Integrate your isolated systems with BatchMaster ERP to build connected ecosystems of all departments. The integration helps to speed up work and do more in less.

- Insights – BatchMaster ERP provides analysis and insights to various data related to sales, production, customers, orders etc. These insights assist manufacturers in decision making.

Conclusion:

By comparing both sides and knowing about centralized and decentralized manufacturing we can say that both have its own importance. Selection of approach depends upon a lot of factors. Hence, before taking the crucial decision, always take a holistic approach and find which approach suits your business.

Whichever manufacturing approach you prefer, BatchMaster ERP is always there to make your manufacturing smoother, and hassle free. To know more about BatchMaster ERP, visit our website.