Intelligence comes from information. Information comes from data. And data comes from ERP. So if we belive in the A equals B equals C equation, it can immediately be deduced that data from ERP systems can directly translate into business intelligence.

As the name suggests, Enterprise Resource Planning or ERP can help enterprises manage their resources, whether it be process, people, information or material.

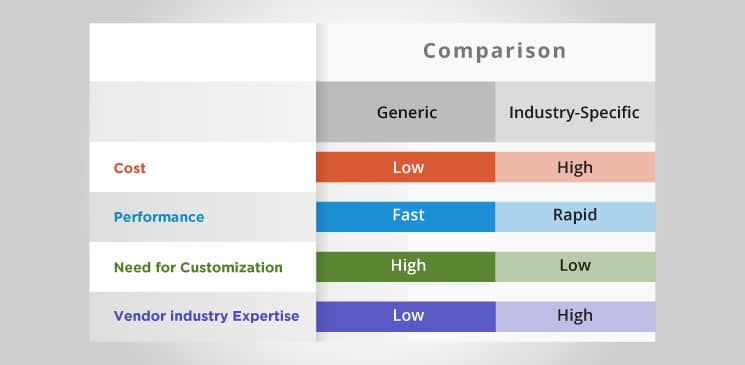

ERP software are broadly divided into two sub-categories, generic and industry-specific.

Generic or “commercial off-the-shelf” ERP software are readymade software products that are available to a broader customer base irrespective of the nature of their manufacturing.

Whereas, industry-specific ERP solutions are curated for unique micro-verticals with relevant operational features for that particular industry.

Variables affecting the choice…

The one-size-fits-all approach doesn’t always work, especially in today’s evolving business landscape. Specialised industries need software that are developed to meet their specific needs.

A few important aspects need to be taken into consideration before choosing between generic and industry-specific ERP solutions.

Depending on the need of the business and the customization required, the following factors influence that decision:

Cost –

The cost of a generic ERP software is generally lower as the vendors sell it to a larger customer base, keeping margins at a minimum.

For non-specialised industries, generic ERP software can be a perfect fit. On the other hand, industry-specific ERP solutions are developed by industry experts. It might drive up the initial cost but the benefits are immense.

Using industry standard practices can result in saving money on other fronts, making the implementation achieve its ROI within the given time frame.

Performance –

It should also be noted that generic ERP can include a lot of unessential features that can slow down the overall performance of the software.

Though it can be argued that the most important features are placed in prominent positions for ease-of-access.

On the contrary, industry-specific solutions exclusively include only the most important industry features in their software. This helps keep the software light and fast.

Customization –

The most important difference. Generic ERP system often need a lot of customization which consumes time, increases cost and elevates risk. Features need t o be added or omitted to serve the specific needs of the industry.

Whereas, industry-specific solutions are tailored to offer a niche based experience to specialized industries. Specific features are included already, cutting down the implementation time.

Vendor expertise –

The lack of expert guidance of industry professionals can make generic ERP software vulnerable to process mismatch.

Generic ERPs can’t really furnish specific business solutions to the industry. On the other hand, industry-specific solutions are based on industry insights and hence offer a variety of solutions to redundant business practices.

Conclusion

Generic ERP and industry-specific solutions are both implemented to simplify business processes. The decision to buy either of them should be made carefully, as the ramifications can never fully be foreseen and pitfalls can never be predicted.

Organizations that don’t consider customization as their priority, tend to implement generic ERP. Whereas, companies that are looking to find solutions to unique workflow challenges are advised to go for industry-specific ERP solutions.

Choosing the right software can make or break the future of your company. Therefore, you should select the right fit for your company after careful consideration of your software implementation goals.

An industry-specific ERP solution can help with optimizing business processes and streamlining the supply chain. If you are looking for a custom-made ERP solution, click here.