Imagine…

Using a screwdriver, instead of a hammer, to hit the nail on the wall. Or, using a shoe, instead of a spray, to kill the ants.

I know you must have done this some time or other. And, you must have been able to complete the work but you felt exhausted.

Moreover, it would not have been that efficient and quick as it could be on using a hammer or spray. Thus, it is very essential that the tools should be used in the right way!

Similarly, when it comes to using a software solution to manage inventory in manufacturing industries, the tools Warehouse Management System (WMS) and Enterprise Resource Planning (ERP) software are often used interchangeably. However, they are not the same.

They are the two different tools designed for distinct purposes. Using either of the tools, manufacturers may be able to achieve the desired outcome but surely sacrifice efficiency and effectiveness.

In other words, it is going to take more time and effort and the result may not be that accurate.

So, if you are a manufacturer, it is important for you to understand the definition and difference between WMS and ERP when selecting the one for your business.

And, this blog post aims to educate you on the same. So read on!

The primary difference between a WMS and ERP

Before knowing the differences between the two, let us first understand what a WMS and ERP technically are.

Warehouse Management System (WMS) is a software solution designed to simplify day-to-day warehouse operations, increase visibility into inventory movements, and improve inventory accuracy by empowering manufacturers to remotely execute and track details of different warehouse operations.

By this, WMS helps manufacturers to ensure efficient and cost-effective movement of inventory across entire supply chain.

Whereas, Enterprise Resource Planning (ERP) is a suite of integrated modules designed to collaborate, streamline, and automate operational activities across entire supply chain.

Acting as a central repository of information, ERP records, manages, and interprets information from product planning, cost and development, manufacturing, marketing, sales, inventory management, shipping, and payment.

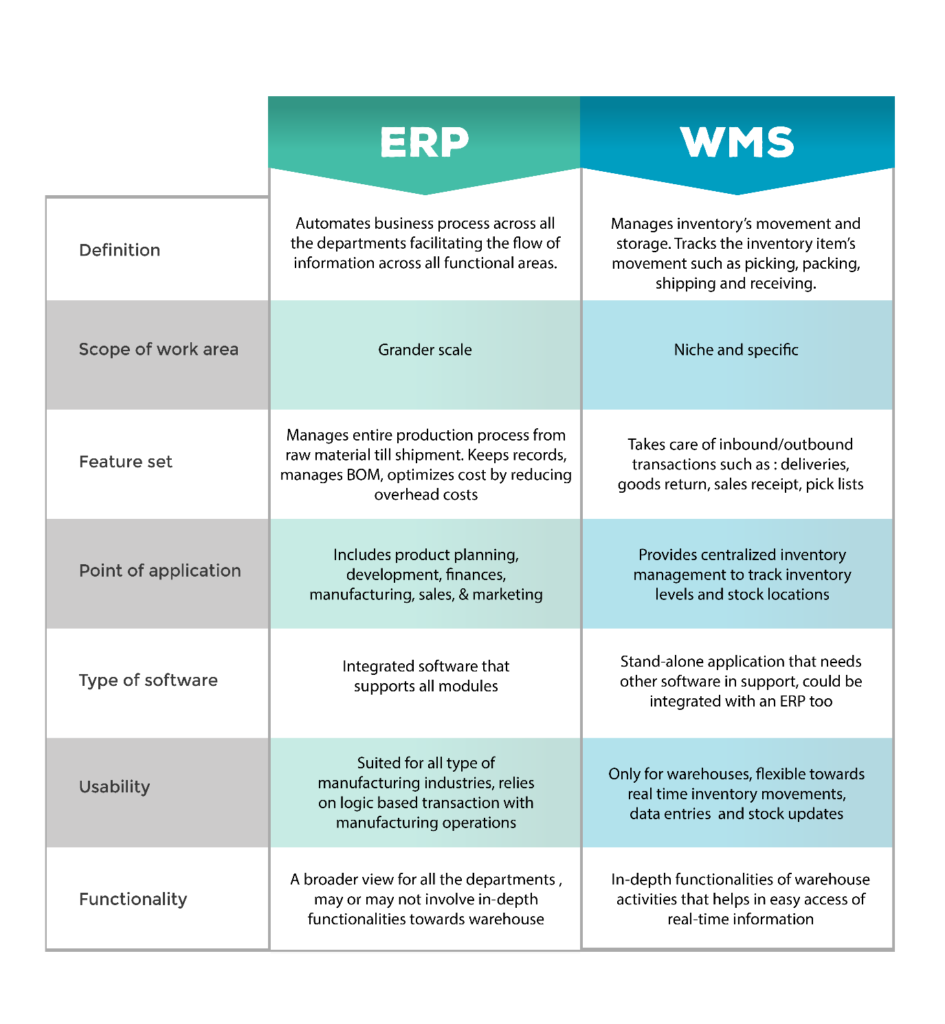

Now, coming to the differences between WMS and ERP.

WMS aims to streamline warehouse operations whereas ERP integrates all departments of the supply chain to facilitate smooth information flow between them.

WMS has the capabilities to track real-time information about the inventory’s picking, packaging, and delivery.

Thus, offers improved visibility and empowers manufacturers with greater control on optimizing the process of order placement.

ERP, on the other hand, offers a seamless flow of information within different departments. For example:

If manufacturers use one WMS, one financial management system, and one to manage manufacturing processes, they will have to gather information manually from different software.

Definitely, the process would be time-consuming, above all error-prone. At the same place, with integration provided by an ERP, this problem gets eliminated.

Which management solution to choose for your business – ERP or WMS?

WMS and ERP systems are both potentially valuable solutions for your company.

However, to decide whether an ERP or a WMS would suit your manufacturing needs, budget, and business goals –

It is always better to define your long-term business goals including the outcome you wish to achieve, and the operational requirement your manufacturing industry needs to manage using the software solution to meet the targeted outcome.

Now, reading this blog you know the differences between the two solutions that will definitely help you accurately determine which would be the best fit for your company’s unique needs.

However, if you still have more queries on the topic, reach our experts. They would be delighted to help you!