Overview-

Imagine a scenario of you migrating to a new place with your family, what points will you keep in mind? Gathering the complete household stuff, packing them properly, and then shifting, making sure that you don’t miss out carrying even a single thing with you that is valuable.

Whatever you do, you will definitely follow an organized procedure for this. Similarly, migrating to a new ERP system is the process of shifting operations and data from the existing system to a new one. The said process demands a flawless procedural flow.

Especially when it comes to food manufacturers, the scenario becomes more complex due to the excessiveness of the data involved.

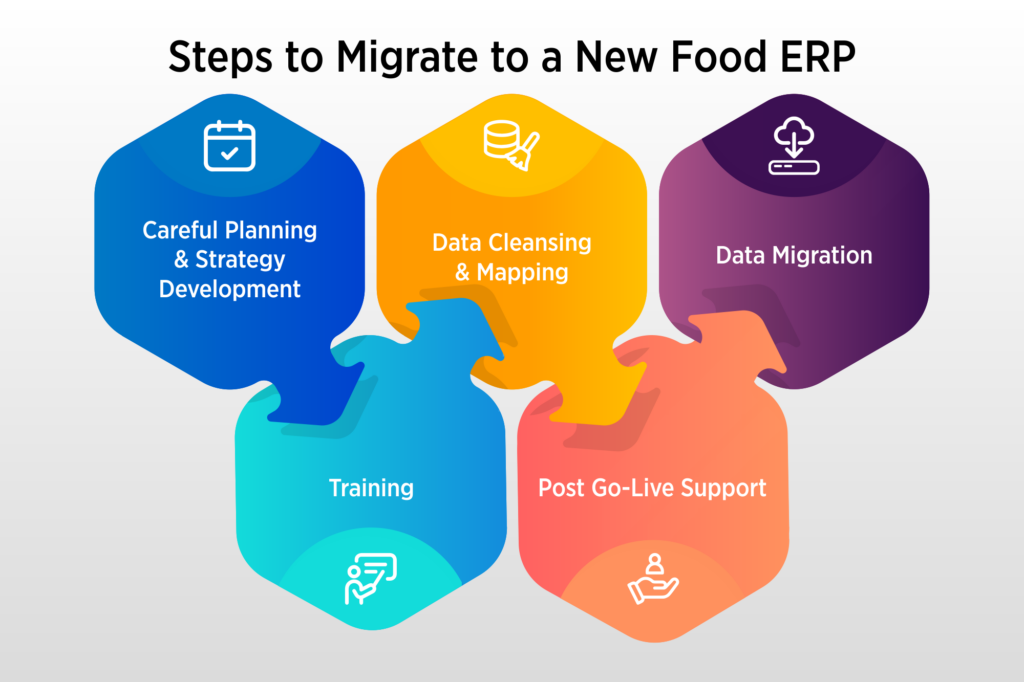

However, ERP migration doesn’t just involve moving data; it is much more than that. Although data migration is considered to be the most vital step during the ERP migration, before that, establishing a foolproof plan and ensuring post-migration support afterwards are processes that can’t be ignored.

Today’s blog will talk about the checklist you should have by your side to ensure a successful migration to a new Food ERP system, flawlessly & seamlessly.

Assessing the Valuables- What Does a Food ERP System Carry

A food manufacturing facility carries a wealth of data that drives its routine operations. Every chunk of data is crucial and needs to be transferred responsibly to the new food ERP software. But, “you can manage only what you know”.

So, to ensure proper migration of this business-crucial data, you should be aware of every single form of data you’re handling.

Without implying that years of industry experience haven’t made you aware of your data, the reality is that ERP implementation is hard, and migration is hardest.

With so many moving parts, it’s natural to overlook certain details. That’s why we’re compiling everything at one place—helping you track every critical data point and ensuring a smooth transition to your new ERP system.

1. Historical and Real-Time Data

The Food ERP solution contains a wealth of data, this includes:

- Inventory records – Stock levels, batch numbers, and expiry dates

- Production schedules – Work orders, recipes, and process workflows

- Supplier and vendor details – Contracts, purchase history, and lead times, background details

- Customer information – Orders, preferences, and feedbacks

- Financial transactions – Revenue, expenses, invoices, and tax details

2. Business Rules and Workflows

Every food manufacturing business has a unique process workflow incorporated within the ERP. These include:

- Recipe and formula management – Ensuring consistent product quality

- Batch tracking and traceability – Meeting food safety regulations

- Quality control checkpoints – Preventing quality defects

- Regulatory compliance rules – Aligning with HACCP, FDA, FSMA, or FSSAI standards

3. Custom Reports and Analytics

Food manufacturers rely on ERP-generated reports for:

- Production efficiency insights

- Supply chain performance tracking

- Sales and demand forecasting

- Compliance and audit records

Now, it’s time to shift our focus onto discussing the strategy food manufacturers should undertake-

Careful Planning & Strategy Development-

“Well-planned is half done”

Successful execution of any task depends on the planning behind it. The better the planning the higher are the chances of it being successful. Similarly, migrating to a new food manufacturing ERP software requires careful planning that minimises disruptions and ensures success.

A well-defined strategy helps food manufacturers maintain their hard-earned operational efficiency and regulatory compliance, preventing setbacks and ensuring continued business growth.

Key Steps to Ensure While Planning

Define Clear Goals & Objectives

The need for migrating to a new ERP system arises when the current legacy system fails to meet business requirements. Therefore, it is essential to identify all pain points in the existing system and set clear objectives for the new ERP.

Assess Business Requirements

Ensure that the new ERP aligns perfectly with industry-specific needs, including processes like batch control and allergen management, while supporting compliance with UK and international food safety regulations, such as HACCP, FSMA, and FDA standards.

Allocate Budget & Resources

Allocate sufficient resources, including budget, time, and personnel, such as stakeholders, IT teams, and operational managers, to ensure a smooth transition.

Data Cleansing & Mapping

Food manufacturing revolves around data, from thousands of recipes to customer order details, supplier/vendor information, and production schedules. Every piece of data is crucial to prevent miscommunication and errors. Even minor inconsistencies can lead to operational inefficiencies and regulatory risks.

Moreover, the benefits of a new Food production software depend significantly on the accuracy of migrated data, making data cleansing an essential step. Data mapping ensures that fields in the new ERP system align seamlessly with existing system data.

Key Aspects of Data Cleansing & Mapping in a Food Manufacturing ERP System:

- Removing Duplicate & Incorrect Data – Eliminate redundant supplier records, outdated ingredient lists, and incorrect inventory data.

- Fixing Data Inconsistencies – Standardise units of measurement, ingredient names, and batch codes to ensure seamless integration.

- Ensuring Data Accuracy – Clean outdated product expiry records before migration and verify that allergen declarations, nutritional information, and HACCP compliance details are up-to-date and accurate.

Data Migration

Once data has been cleansed and mapped, the next crucial step is data migration. Continuous communication between stakeholders and the data migration team is essential to ensure the process is carried out responsibly and accurately.

Key Aspects of Data Migration:

- Rehearse in a Sandbox Environment – Before performing large-scale migration, a trial run in a controlled environment helps identify potential issues, refine strategies, and ensure a smooth transition.

- Execute the Migration – Once testing is successful, the actual data migration process can begin. It involves:

- Extracting existing data from the legacy system.

- Converting data into the format and structure supported by the new ERP system.

- Uploading the converted data into the designated fields within the new ERP system.

- Validating & reconciling the migrated data through quality and consistency checks to ensure accuracy, eliminate errors, and avoid information gaps.

Training

Proper training is mandatory to help employees familiarise themselves with the functionalities of the new ERP system. Without adequate training, users may resist change, preferring traditional methods over the new system.

Key Areas of ERP End-User Training:

- System Navigation – Training users to navigate the ERP interface and locate key functions.

- Core Functionalities – Educating users about system features relevant to their roles.

- Support & Troubleshooting – Ensuring users know how to seek help and resolve common issues efficiently.

Post-Go-Live Support

The migration journey does not end with implementation. Continuous monitoring of system performance, data integrity, and user adoption is essential for a smooth and successful transition.

If any issues arise, they should be addressed promptly, with ongoing measures in place to support continuous system optimisation and upgrades.

Gain a Competitive Edge With BatchMaster ERP

Migrating to a new Food ERP system is a complex process that demands careful planning and execution. However, selecting the right ERP software plays a pivotal role in ensuring a smooth transition.

With over 30 years of industry expertise, BatchMaster ERP for the Food Industry is designed to address the unique challenges of food manufacturers, streamlining operations and ensuring compliance. BatchMaster quickly understands your needs, making ERP migration effortless and helping you achieve your technology goals seamlessly.

To know how we bring our expertise right at your doorstep, book your free discovery call today.