Enterprise Resource Planning (ERP) systems have come a long way, and it’s evident that the trends we’re witnessing now will only grow stronger in the year 2025. With technology advancing faster than ever, businesses constantly adapting, and the push for smarter, more efficient solutions, ERP systems are evolving to meet the challenge.

Today, they’re at the heart of digital transformation, seamlessly connecting every part of a business to fuel growth and agility.

Talking about advanced process manufacturing industries, we all know that their workflow and processes are extremely complex/intricate. These industries rely on complex, continuous, or batch processes that use physical, chemical, or biological processes to convert raw materials into final goods.

Industries like food, pharmaceuticals, paints, chemical fall under this category. And, to simplify the workflows and manage their production from start to finish an Advanced Process manufacturing ERP software becomes a must-have.

In the pharmaceutical industry, for example, vaccine production occurs under extremely clean and highly regulated conditions. Raw ingredients are mixed using precise chemical procedures, where even a slight variation can compromise an entire product line.

To ensure product quality and safety, it’s crucial to monitor production batches continuously and meet all compliance requirements. While this is just one example, ERP system has broader capabilities.

An ERP for Process Manufacturing handles everything—from raw material procurement to quality control, inventory management, production, and distribution—all while ensuring strict adherence to industry regulations. Today’s ERPs are also integrating advanced technological tools, such as Artificial Intelligence (AI), the Internet of Things (IoT), and Business Intelligence (BI).

These innovations enhance real-time monitoring, predictive analytics, and decision-making, allowing businesses to optimize their processes, increase operational efficiency, and maintain compliance. With such capabilities, modern ERPs are not just software solutions; they are key drivers of flexibility and success in process manufacturing industries.

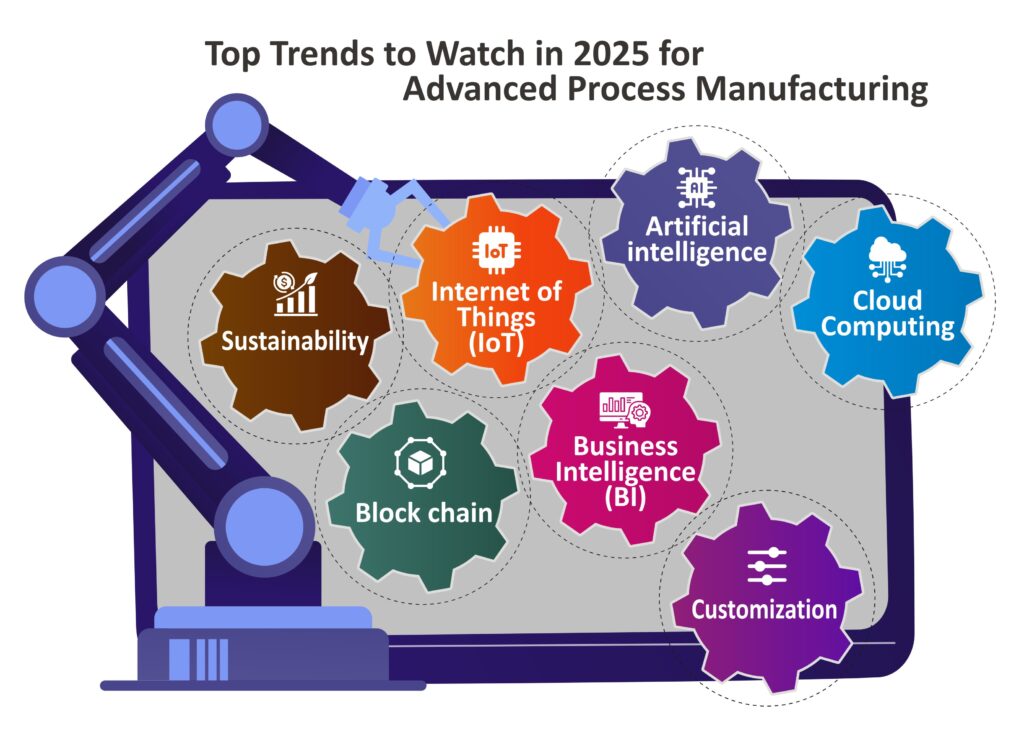

Top Trends to Watch in 2025 for Advanced Process Manufacturing Industries

Internet of Things (IoT) in ERP:

IoT is revolutionizing the process manufacturing industries by integrating and connecting machines, sensors, and equipment directly to Process Manufacturing ERP System. This year also IoT will enable real-time monitoring of equipment performance, enhancing predictive maintenance and minimizing downtime. Integrating IoT with ERP systems will provide businesses with live, actionable insights from their manufacturing processes, boosting performance and efficiency simultaneously.

Artificial intelligence (AI) in ERP:

AI is already transforming ERP systems, and in 2025, users and manufacturers can look forward to even more advanced AI-driven features. From enhancing decision-making and predictive maintenance to demand forecasting, AI will play a crucial role.

For example, AI can analyze historical sales data and market trends to forecast demand for seasonal products, ensuring optimal inventory levels. It can also detect patterns in machinery performance to predict failures before they occur, minimizing downtime. By leveraging such capabilities, businesses can reduce risks, improve efficiency, and stay ahead in a competitive market.

Cloud Computing:

Cloud-based ERP systems have become the go-to solution for managing business data, offering 24/7 global access. Their popularity is growing due to lower upfront costs, no hardware requirements, and SOC-certified security. In 2025, cloud ERP systems are expected to become the standard, providing real-time data access and seamless scalability for businesses to expand without infrastructure concerns.

Built-in disaster recovery and backup capabilities ensure business continuity during unforeseen events. Cloud ERP represents the future of agile, efficient, and secure business operations.

Business Intelligence(BI) in ERP:

As data volumes grow, advanced analytics will play a crucial role in enhancing ERP systems. In future also, ERP systems are expected to integrate more sophisticated Business Intelligence (BI) capabilities, offering deeper insights into production, finance, and inventory data.

Manufacturers will leverage BI to perform detailed analysis, spot emerging trends, and make proactive, data-driven decisions to optimize profitability, reduce waste, and improve overall efficiency.

Customization in ERP:

One-size-fits-all ERP solutions no longer meet the diverse needs of process manufacturing companies, as each business has its own unique requirements. In 2025, ERP vendors are expected to offer more modular, adaptable solutions, allowing manufacturers to select the features and functionalities that align with their specific needs.

This increased flexibility will enable them to scale and adjust their ERP systems as their operations evolve, ensuring they only pay for the capabilities they actually need.

Blockchain for Supply Chain Transparency:

Blockchain technology acts as a digital ledger, ensuring that records are secure, transparent, and tamper-proof. In 2025, it will revolutionize supply chain management by enabling manufacturers to track every step in real-time. This will allow companies to verify product authenticity and maintain transparency throughout the process.

Industries like pharmaceuticals and food manufacturing, where product traceability and regulatory compliance are critical, will see the greatest benefit from integrating blockchain with ERP systems, ensuring more secure and efficient operations.

Sustainability in ERP:

To reduce their environmental impact, ERP systems will become essential tools for achieving sustainability goals also. From this year and beyond, Process Manufacturing ERP Software are expected to have features that can track sustainability efforts, reduce carbon footprints, eliminate paper usage, and minimize waste. This way, it will businesses optimize resource use, reduce waste, and monitor energy consumption, helping them meet or even exceed environmental regulations and green targets.

What Will Businesses Gain from Integrating these trends in Process Manufacturing ERP Software?

Advanced process manufacturing business can gain both operational efficiency and a competitive advantage by integrating ERP systems with cutting-edge technical breakthroughs. As ERP systems evolve in 2025, manufacturers will profit from:

1. Competitive Edge:

With the help of advanced technologies like AI, machine learning, and real-time data analysis, manufacturers can stay ahead of the competition. An ERP for Process Manufacturing gives them insights into every part of the business, allowing for quicker responses to market changes, smarter decision-making, and continuous improvement. This agility and data-driven approach help companies stay a step ahead in a competitive market.

2. Increase in Operational Efficiency:

Businesses can increase operational efficiency by reducing manual labor intervention and optimizing procedures. Automation, real-time data, and smart scheduling workflows will improve resource utilization, streamline operations, and reduce bottlenecks. Furthermore, enhanced forecasting and predictive analytics will offer better planning, allowing manufacturers to minimize costly downtime and increase total throughput.

3. Accelerated New Product Development:

R&D teams can use data insights to innovate and bring new products to market faster than their competitors. With access to real-time details about materials, costs, and production schedules, they can prototype more quickly and choose the best product options.

For example, a food manufacturer could quickly adjust a recipe based on current consumer trends, ensuring that the product aligns with market demands. By understanding consumer preferences through ERP, businesses can develop cutting-edge products that meet changing needs and stay ahead.

4. Better Decisions:

Comprehensive and detailed dashboards that offer real-time data insights and predictive analytics are now a standard part of ERP systems. This enables manufacturers to make informed and data driven decisions to improve performance in the short term and spur growth in the long run.

5. Better Collaboration:

ERP systems integrated with advanced techniques facilitate better communication and collaboration among various departments in a company such as manufacturing, sales, R&D, and finance by making integrated data available throughout the firm.

This comprehensive picture of the business guarantees that all teams’ goals are aligned thereby resulting in shorter response times, improved coordination, and more successful product releases.

6. No Legal Penalties & Fines:

As industry requirements change, ERP solutions help manufacturers stay and exceed compliances, meeting both global and local norms. Businesses can more easily traverse regulatory landscapes with automated alerts and extensive tracking, avoiding potential penalties and protecting their market reputation.

To wrap up our topic, we can conclude that the future of ERP software in advanced process manufacturing looks bright. Advanced tools are paving the way for more efficient, transparent, and sustainable operations.

Manufacturers who embrace these trends in 2025 will not only stay ahead of the competition but will also optimize their processes and continue to deliver high-quality products while meeting regulatory standards.

ERP systems are more than just software—they’re the backbone of innovation, operational excellence, and growth. Solutions like BatchMaster ERP are already designed to handle the complexities of advanced process manufacturing, ensuring compliance, driving efficiency, and setting businesses on the path to success.

The future is now, and with a future-ready ERP system, manufacturers can unlock new growth opportunities in an ever-evolving market. Contact our team of experts today, as they are happily assist you.