What is the significance of supply chain in the pharmaceutical manufacturing industry? Or, how important is it to manage the supply chain in the pharmaceutical manufacturing industry?

The circumstances triggered by the outbreak of the COVID-19 in late 2019, and which still are very much prevalent, offer answers to these questions.

The pandemic, and the ensuing lockdown, affected businesses across the globe, causing disruptions in virtually all the sectors- pharmaceutical manufacturing included.

Unavailability of labor, along with the suspension of the logistics & transport services, affected the pharma companies’ operations big time.

And China — where the novel coronavirus originated — being the hub of the world for manufacturing and supplying of medicinal raw materials, it didn’t take long for the businesses to run out of stock, and even, shut down their operations. This happened as the pandemic derailed the global pharma supply chain.

What are the lessons that the pharma manufacturing businesses learned from the pandemic?

So, well, what this pandemic has essentially done is that it has:

- Emphasized on the need to reimagine the supply chains- i.e., building new, self-sufficient, and more resilient supply chain networks,

- Made the entire world realize the importance of supply chain, but most importantly,

- Made the pharmaceutical manufacturing businesses realize the need to manage the supply chain.

No doubt, the pharma supply chain needs a thorough revision. The link between the laboratory and the marketplace, pharmaceutical supply chain at present is an extremely complex network that includes many stakeholders such as the manufacturers, distributors, suppliers, retailers, and the end consumer.

The stakes are pretty high in the pharma supply chain, as the pharmaceutical companies need to ensure that the drugs are distributed correctly so that both the company’s reputation as well as customer satisfaction remain intact.

On the other hand, an ineffective supply chain could disrupt the healing processes of patients and produce negative effects on public health, according to a Kaiser Family Foundation report. But keeping the supply chain well-oiled, and free-flowing isn’t easy.

What are supply chain challenges in pharma industry?

The business environment is increasingly changing, and in this changed scenario, the pharma manufacturers are required to supply high quality products, deliver fast responses, and make their dynamic competencies better.

But to achieve that, the pharmaceutical manufacturers need to deal with their own set of supply chain challenges, including supply chain visibility, drug counterfeiting, cold-chain shipping, among others. These challenges are complicated, and can have economic, social, and even legal considerations.

Furthermore, lack of coordination, inventory management, absent demand information, order management, shipment visibility, and costs, are some of the major complications that pharmaceutical companies encounter.

How ERP can help manage the pharma supply chain?

To understand the story so far in layman’s language, pharma manufacturers struggle to manage the supply chain, and face a number of hurdles in the form of challenges that threaten to bring their operations to a grinding halt, or cause delays that can affect the business adversely.

Take for example certain raw materials running out or not being replenished in a timely manner.

Here’s where a pharma ERP comes into play, mitigating this and doing a lot more to efficiently manage the supply chain of a pharmaceutical manufacturing company.

It helps pharma businesses gain operational efficiency, enhance productivity, and achieve profitability, besides keeping them agile so as to adapt to various changes in market scenario.

Supply chain management, in fact, has been an integral part of ERP solutions that help manufacturers interact with various supply chain partners to obtain the raw materials and resources at the right time and in right quantity to bring the end product to the market.

This, in turn, helps boost plant productivity, enhance product quality, and cut down on manufacturing costs.

Let’s explore in detail how pharma manufacturers can manage the supply chain using an ERP software for pharmaceuticals:

Through Demand and Planning:

Using a pharma ERP software, pharma manufacturers can automatically create demand when orders are received, determining the quantities of stock and inventory required and ensuring timely replenishment.

Its MPS & MRP module comes in handy, assisting them with how much and when is to be produced, and how much, and when the required material is to be procured to meet this schedule, respectively.

Through Purchasing, Material, & Supplier Management:

A pharmaceutical manufacturing ERP system in pharmaceutical industries provides a more effective way to handle procurement and supply of the raw materials, services and other resources that are needed across the supply chain.

Allowing pharma manufacturers to quickly identify their key suppliers, it provides a platform to evaluate their risks as well as ability to meet essential supply requirements of right quality standards and timeliness.

This assessment could help them avoid sudden disruptions in supply chain, like the one caused by the COVID-19 pandemic, and deal with lack of information, and intelligent procurement (knowing where to source from, and when).

Through Monitoring and Maintenance:

The ability to monitor, review and alter supply chain efforts and activities in real-time is essential for ensuring your pharma manufacturing business is able to maintain the flexibility needed to stay competitive and ensure cost-effective operations.

A pharmaceutical manufacturing ERP facilitates the same.

Through Measurement and Assessment:

Managing a pharma supply chain using multiple disparate systems and workflow processes makes it impossible for the manufacturers to compare actual activity against projected goals and targets.

But ERP systems for pharmaceutical manufacturing offer an organized way of doing things that ensures any variances throughout the supply chain are quickly identified and promptly addressed.

Through Managing Shipment:

A pharma manufacturing software immediately generates an invoice that is to be sent to the customer as soon as the item gets shipped.

Additionally, it helps in maintaining a central repository for all the shipments along with the delivery details to ensure the items are delivered on time.

Another critical aspect that ERP implementation in pharmaceutical companies serves in the pharma supply chain is the cold chain.

Few essential drugs, such as the vaccines, are temperature-sensitive, and hence required to be moved through the supply chain with necessary precautions, so as to retain their efficacy while in transit.

An ERP, when integrated with cold chain management tools, ensures the temperatures are monitored in real-time and kept in the defined tolerance range to keep the vaccines effective, safe and secure for the consumers.

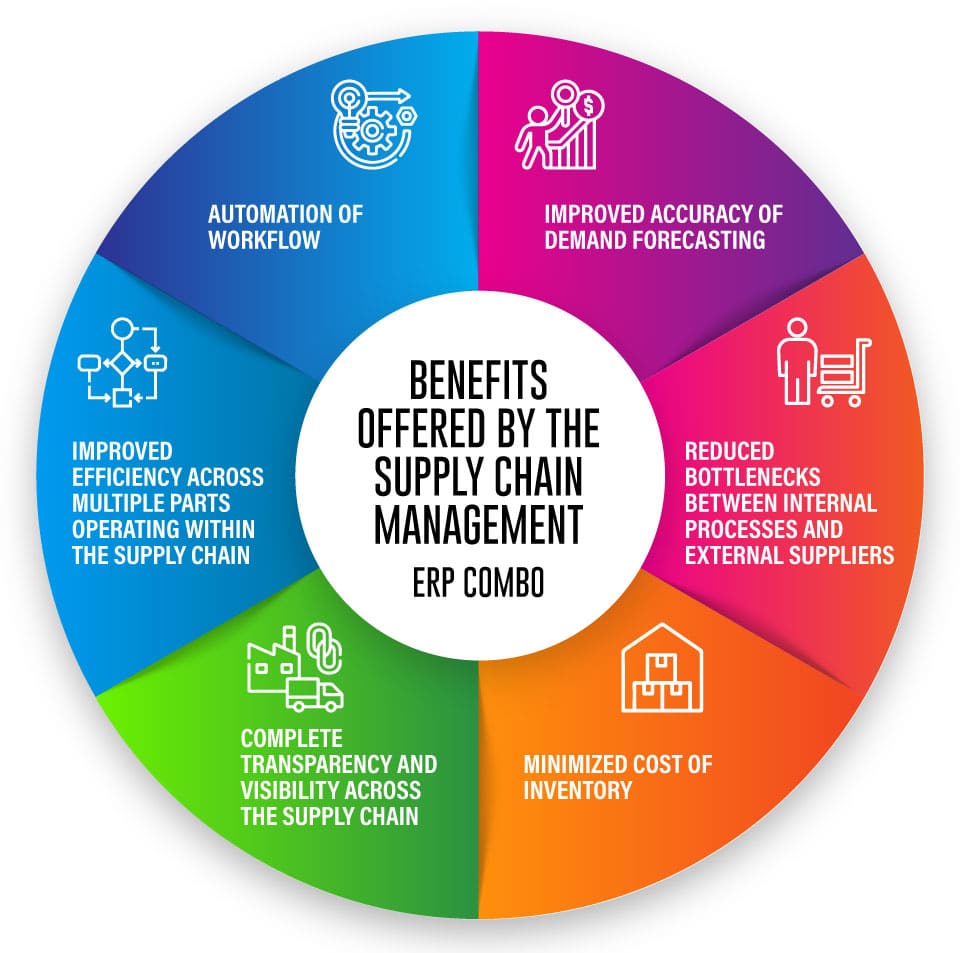

Benefits offered by the Supply Chain Management – ERP combo

A modern ERP automates the entire workflow from procurement to product delivery, thus streamlining the path materials take from supplier to customers.

At the end, it helps the different stakeholders of the pharma supply chain keep a total control of cost of storage and meet customer demand.

Some of the top benefits an ERP software offers to the pharma manufacturers in their quest to manage the pharma supply chain are:

- Improved accuracy of demand forecasting.

- Minimized cost of inventory in case of large-batch production process.

- Reduced bottlenecks between internal processes and external suppliers, ensuring availability of resources required across the supply chain.

- Complete transparency and visibility across the supply chain that facilitates more informed and balanced decisions.

- Improved efficiency across multiple parts operating within the supply chain.

- Automation of workflow that helps bring down the costs.

BatchMaster ERP for Pharmaceuticals helps businesses manage the supply chain with elan!

It has been established beyond reasonable doubt that an ERP solution such as BatchMaster ERP for Pharma plays a crucial role in ensuring the smooth functioning of the pharma supply chain by facilitating planning, inventory optimization, monitoring, and assessment, and by giving end-to-end visibility to all the activities of the supply chain in real-time.