Footwear is one of the largest and most important segments of the leather industry. This industry provides customers with a diverse range of shoes, sneakers, slippers, and sandals, among others.

Over the last two decades, a large number of small and medium-sized manufacturing businesses from this sector have grown into large corporations, and each of them is implementing cutting-edge technologies to produce high-quality footwear.

Keep on reading this blog to learn more about ERP software for footwear industry.

Table of content:

- Overview

- Challenges faced by the footwear industry

- The role of ERP software in the footwear manufacturing industry

- Summarizing thoughts

Overview

The footwear industry is massively huge and involves several multiple operations such as manufacturing, procurement, distribution, and retailing.

What is unique about this industry is that the items produced must be produced in different sizes, styles, and colours.

Apart from the inventory management and supply chain management functionalities, retailers and manufacturers also need to have a system that can handle all operations from the time material enters the warehouse to the time the finished product reaches its consumer.

Nevertheless, the right ERP software for footwear industry helps in coordinating all the specific business processes and, also ensures that the right products are stocked in order to meet customer demands.

A specific footwear ERP system recognizes how complex footwear products order can be, and how important it is to make sure the customers get exactly what they want, when they want it.

So, let’s look at the topic in more detail to discover what challenges footwear manufacturers face and how ERP software can resolve them.

Challenges faced by the footwear industry

Inconsistent orders, ever-changing market trends and requirements, the need to operate at lower costs, continuous pressure for offering better value, and different compliance requirements in different countries have affected the footwear sector.

The manufacturers also face challenges in managing multiple warehouses and stores. Besides, they need to deal with the strict taxation regulations, concentrate on lowering logistical costs, and maximize stock usage to avoid wastage.

Then, they should also focus on timely and efficient product delivery while ensuring that the entire production process is managed smoothly.

All of these difficulties have made the footwear industry’s management more complex, and the amount of data that needs to be handled at various stages of the supply chain has increased.

This calls for a tool that can eliminate all these intricacies and help the footwear manufacturing industry streamline their operations and grow enormously. A footwear manufacturing ERP becomes one true solution in order to achieve this.

The role of ERP software for footwear industry

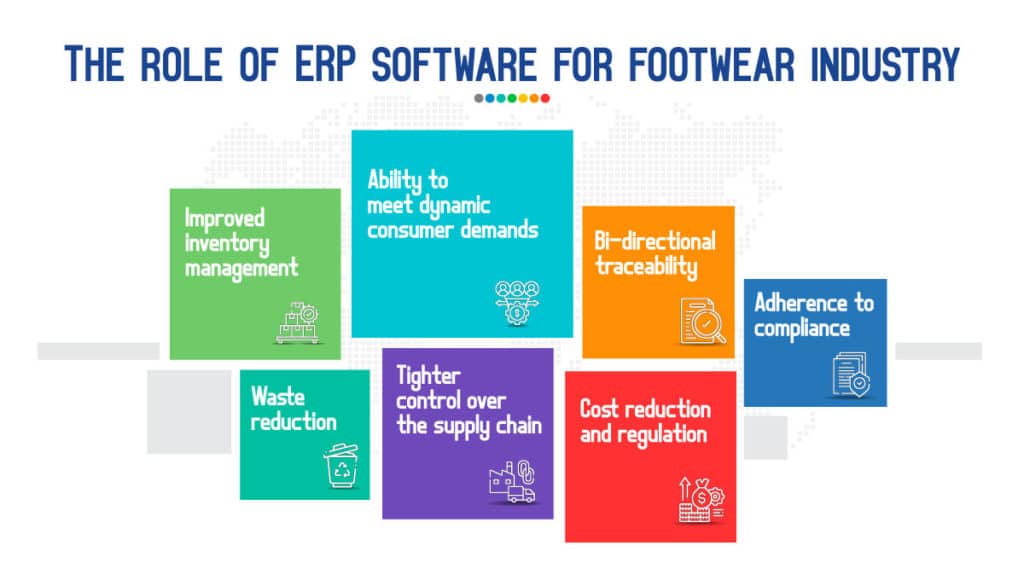

ERP systems specially designed for footwear processing units solve a number of challenges by integrating all areas of business, like procurement, inventory, production, operations, sales, accounting, and finance, over a unified platform.

This kind of “information hub” delivers accurate, real-time information crucial to the manufacturing and various processing operations.

Footwear ERP software provides invaluable benefits to the manufacturers who are seeking to reduce costs, manage growth, streamline processes, and gain a competitive advantage over their competitors.

From procuring the raw materials for the production to its cutting, stitching, providing various patterns, colours, and textures till its packaging, and distributing the product to the end-user, it maps everything. Let’s have a closer look:

– Tighter control over the supply chain

Tailor-made footwear ERP enables businesses to adopt best practices in order to increase profits in this highly competitive market by gaining control of the full supply chain, from procuring raw materials to producing elegant footwear.

– Adherence to compliance

With timely paperwork and key functionalities that facilitate adherence to the established regulatory norms, ERP helps footwear manufacturers win over essential legal obligations.

It enables them to stay ahead of the quality requirements, controls, and statutory rules pertaining to the footwear business’ processes.

– Improves inventory management

The footwear manufacturers need to have a strong network of suppliers and vendors, and an ERP helps with it to a large extent. It streamlines the procurement process and ensures that it is completed quickly and smoothly for uninterrupted production.

ERP not only helps build a procurement plan, but also helps businesses track their logistics in real-time and maintain procurement schedules.

At any point in time, the quality of raw materials and processes can be evaluated. With the help of batch numbers, managing and tracking inventory becomes easier.

Manual data entry can be avoided with barcode integration, and data is immediately available on the system.

– Waste Reduction

ERP improves efficiency and productivity by helping businesses optimize complex processes, prevent data re-entry, and improve functions such as production, order completion, and delivery.

Following the path of lean manufacturing, footwear ERP software eliminates wastage by supporting just-in-time production and saving money and labour for warehouse storage and additional labour.

– Ever-changing consumer demand

Consumers demand new variety on a regular basis, and manufacturers find it hard to strike a balance between R&D and constant innovation.

ERP solves this problem with its intuitive laboratory module, which facilitates simpler R&D while keeping up with the original methods. ERP enables businesses to manage various shoe colours and variants in order to satisfy customer demands.

– Regulates costs

Footwear production requires huge investments in machinery and manpower, leaving little room for profit margins.

The out-of-the-box costing module in ERP aids with “what-if” cost analysis and deciding pricing policies. It helps in optimizing costs at every possible point.

– Bi-directional Traceability

ERP helps in the early detection of faulty batches just at the hint of discovering compromising raw material being used in the production.

Traceability can be performed bi-directionally with ERP as it offers comprehensive stock position anywhere within the supply chain, including lot details simply at the click of a button.

This also helps in product recalls; in case any faulty batch has been dispatched.

– Summarizing Thoughts

An ERP solution helps footwear manufacturers obtain a consistent and assured quality product, with improved packaging, tighter control over the costs, and increased profit margin.

BATCHMASTER HELPS FOOTWEAR MANUFACTURERS PUT THEIR BEST FOOT FORWARD

BatchMaster ERP for footwear industry is a competent and flexible footwear ERP software that allows manufacturers to consolidate all their operations across different units and locations, automate the entire system, store, and access data in one place, and effectively control plus streamline compliance activities.

Available on premise, cloud, and web, it is useful for small and medium companies, as well as the large enterprises having their manufacturing plants in multiple locations.

In fact, businesses of all sizes can save costs on IT infrastructure and maintenance with BatchMaster.

If you’re a footwear manufacturer looking to transform your business operations, contact our experts at sales@batchmaster.com, or request a free demo to see how BatchMaster ERP is specialized to your industry’s most-specific requirements.