COVID-19 continues to bulldoze the world. With the World Health Organization (WHO) upgrading its global risk to “very high”, it has undoubtedly become a serious challenge for humanity, affecting hundreds of thousands of people worldwide every day.

The pandemic hasn’t spared the businesses either, as the global economy and international markets continue to plunge with the coronavirus spreading from China to other countries across the globe thick and fast.

While this is the present, the future doesn’t look good either, with the Organization for Economic Co-operation and Development (OECD) warning that the virus could cut global economic growth in half.

The business leaders across different countries, along with their governments, are seeking to urgently act to keep ahead of this rapidly-changing pandemic and assess its impact and the implications which will be felt for the months to come.

The supply chain issues- in numbers

The decisions taken by the leaders to prevent further spread of the virus include worldwide travel restrictions and quarantines.

These decisions have inadvertently disrupted the global supply chains, resulting in suspended business operations and shrinking revenues.

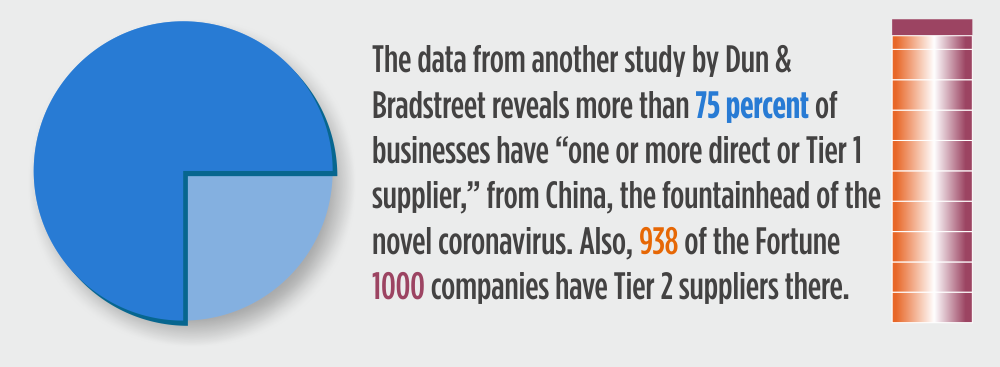

The results of the recent survey conducted by the Institute of Supply Management (ISM) on COVID-19 and its short- and long-term impacts on the world’s supply chains, reveal that around 75 percent of companies are reporting supply chain disruptions due to coronavirus-related transportation restrictions.

Furthermore, more than 80 percent companies believe their organizations will experience some impact because of COVID-19 disruptions. Whereas 55 percent of companies plan to downgrade their growth outlooks (or have already done so).

These are massive numbers.

The actual supply chain problems

The rapid spread of the virus has meant that several countries are in lockdown, and their economies crippling.

The supply chain function in such times is extremely critical to maintain operations. However, the disruption to supply chains, and a sudden and massive rise in demand, has resulted in goods and services not reaching their destinations quickly, safely, and securely.

Take, for instance, the healthcare sector where supply chain disruption has created a severe shortage of products like personal protective equipment (PPE), masks, and testing kits.

Hoarding, triggered by panic buying, has meant that food and grocery items are going off the shelf too soon, with no signs of quick replenishment.

What’s the fix?

With COVID-19 breaching the defenses of the supply chains, manufacturing companies worldwide need to develop COVID-19 response and take swift actions to stabilize and build a stronger supply chain in the long-term.

There is a pressing need for businesses to make their supply chains more resilient so as to manage future challenges.

The efforts to add more resilience to the supply chain include non-dependency on a single source, and to have a back-up supply source to ensure normal supply levels can be restored at the earliest.

Investments in making supply chain resilient can pay rich dividends, as a study by Bain & Company suggests they can deliver a 15 to 25 percent improvement in plant output and a 20 to 30 percent rise in customer satisfaction.

Following are some more ways to fix supply chain problems in COVID-19:

Supplier risk assessment:

In the present scenario, it makes sense for the manufacturing companies to quickly identify their key suppliers, and to evaluate their risks as well as the ability to meet essential supply requirements of right quality standards and timeliness.

This assessment could help them avoid sudden disruptions in the supply chain, deal with lack of information, and intelligent procurement (knowing where to source from, and when).

Inventory and the flow of goods’ monitoring:

With people going in panic buying mode, and with supply chains getting derailed, it is important for the manufacturers to monitor inventory levels and improve the visibility of all inflow of goods, along with looking into smooth material handling and adequate manpower availability.

Make supply chains intelligent:

Use of intelligent automation and analytical tools can help manufacturers gather insights around supplier performance, supply chain diagnostics, market intelligence and risk management.

Manufacturers/Retailers should use technology-driven dashboards to look to try and gain real-time visibility into the supplier’s end–supplier production schedules, shipment details, etc. to understand and foresee any material flow disruption situations beforehand.

Make work & workplace safe:

Business, especially those working at the front line, need to equip their employees who handle food, logistics, or delivery, with personal protective equipment (PPE).

This is not just for the time being, but also for a good time along the line, to ensure the safety of the workers as well as consumers.

It is also wise to stock up on PPE supplies to mitigate the risk of future shortage.

There are other precautionary measures too which should be taken, such as making the employees aware of the hygiene and sanitization standards to be met, need to maintain social distancing even after COVID-19, and take necessary precautions while coughing and sneezing.

These are elementary measures, but regulatory bodies are working continuously to bring about new laws and standards to reduce the impact of COVID-19.

This might include updating SDS, generating labels, following SOPs, and such.

Having the agility to adapt to these new laws and regulations is the key for the manufacturers.

This is critical from ‘fixing the supply chain problems’ point of view, as these measures will inspire confidence among the end consumers, and help the supply chain get going again.

Contingency plans:

Manufacturers, along with their key suppliers, should look at creating mutually.

Carefully taking into stock the liquidity positions (and potential options to invest, or borrow), and people’s availability, etc., a post-coronavirus long-term supply chain continuity plan should be readied.

This plan should be readied after supply chain simulation, i.e. modeling new supply chain strategies based on the changes being brought about by COVID-19 to the business, as well as operating model, and the related impact on supply chains.

Think local:

Indian Prime Minister Narendra Modi recently spoke in his address to the nation during the lockdown, “It is time to be vocal about local.”

The idea behind his “vocal for local” clarion call is to propel India to emerge as a leading start-up and innovation hub, and subsequently, a crucial supply-chain hub in the post-COVID-19 world.

Going forward, manufacturers becoming self-reliant, and not self-centered, would be an ideal way to fix the supply chain problems.

In a nutshell

COVID-19 has posed a lot of problems in front of mankind. Businesses too have suffered, and are facing challenges such as cash crunch, global supply chain disruptions, and a shifting consumer mindset, among others.

However, we humans have the ability and the tendency to bounce back from the most difficult of situations, and this too shall pass, but with a few changes going forward.

In the post-COVID world, businesses will have to introduce changes throughout the breadth of businesses, including more resilient supply chains, responsive risk management operations capabilities, smarter contingency plans, and a push for localization of supply chains to a greater extent, among others.

How can BatchMaster help?

BatchMaster ERP can help process manufacturing businesses deal with the immediate challenges of the global COVID-19 crisis.

In the long term too, it can help your businesses create a resilient, responsive, flexible, and intelligent supply chain, so as to avert any future supply chain crisis.

Get in touch with our experts to know more about our products, or to schedule a free demo.