BATCHMASTER ERP for Injectable

What are the Major Challenges in Injectable Manufacturing Industry?

Being closely associated with dermatological treatments, the various injectable mandatorily need to assure FDA and other regulatory authorities that they deliver extremely safe, hygienic, and reliable products. The manufacturing also demands tight control over processes so as to ensure that the changes to formulas and procedures are done only by authorized personnel. Moreover, these products find applications in wide arena like dermatological centers, spas, and beauty clinics. Therefore, an efficient supply chain management is required to locate and fulfill the gap in distribution. Further, the market is also subjected to various collaborations, contract manufacturing, and loan licensing, which involves a lot of paper work and monitoring of inventory movements, job works and work orders. Maintaining competitive costs also become the top concerns to gain maximum acceptance amongst clients.

Would you like to learn more about our Cosmetics ERP Software?

Cosmetics Industry

How does ERP help in Injectable Manufacturing Industry?

BatchMaster ERP is perfect for Injectable manufactures to streamline operations, maximize productivity, and boost savings. It keenly focuses on formula security, simplifying batch processing, accurate planning, timely deliveries, & continuous R&D. By employing specific clinical observatory trial tests at suitable points across the value chain, the software assures high quality and meets all the regulatory compliances. Clean and hygienic packaging with appropriate labels in desired format is yet another requirement of injectable industry that is fulfilled by BatchMaster suitably well. Plus, tedious laboratory calculations based on the physical properties, bi directional traceability to cope up with audits and timely recall compliance can be performed on a blink of an eye.

Our products have a proven integration to SAP Business One, Sage 50/100/200/300, QuickBooks, and Tally.ERP 9 which means you can easily upgrade to BatchMaster without having to shun your financial software.

Key Features of Injectable ERP Software

- Formula design based on Physical Properties analysis like potency and strength

- Formula Security to support Intellectual Property Rights

- Supports FDA and other Compliance requirements

- HAZMAT Bills of Lading, VOC, and SARA Reporting

- BOM and suitable packaging options

- Bi-directional Lot Traceability

- Shelf-Life/Expiration Date

- Vendor Approval and Management

- Stability Testing

- Non-Conformance and CAPA

- Complete Bi-directional Traceability

- Customized COA (Certificate of Analysis) Reports

- Separate Costing of Formula and Packaging Materials

- New Product Development , R&D, and Its Costing

- Warehouse Management and real time tracking of inventory movement

- Material substitution in formula and Revision Tracking

- Supports Multiple Units Of Measure

- Make-To-Stock and Make-To-Order Operations

- Contract Manufacturing and Loan Licensing

- Material Production Scheduling (MPS) Material Requirement Panning (MRP) for optimum raw material procurement and order processing

Benefits of BatchMaster ERP for Injectable Manufacturing

- Supports new product development with ease

- Make high-quality, & cost-effective products

- Helps you meet legal standards

- Increases profit margins

- Ensures no shortage of material during production

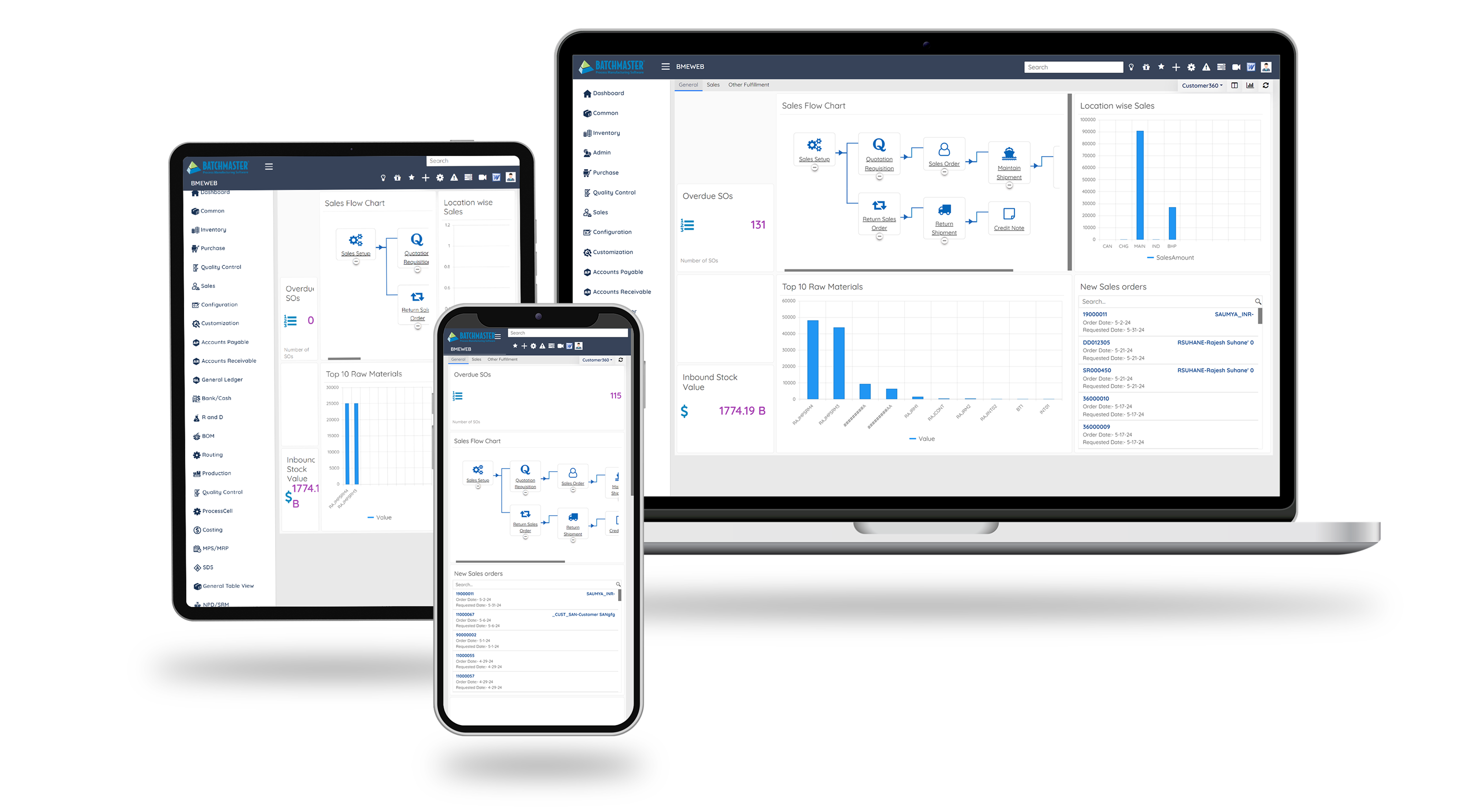

Run Our Manufacturing ERP With Your Existing Financials

Upgrade to our ERP without missing a beat in your financial and accounting routines. BatchMaster ERP offers seamless integration with Tally, QuickBooks, Sage 50/100/200/300, SAP Business One and other popular systems, ensuring a smooth transition.

Web/Cloud Deployment Available

Give your small, mid-size, or large-scale businesses the power of our ‘Cloud ERP’ solutions, and enjoy the benefits of leveraging the cloud.

Brochures

Looking To Find Best Solution for Your Business?

Allow our expert team of solution consultants to review your business operations so that they can offer you the best-possible solution, either on premise or in the cloud, to meet all your industry-specific needs