Bakery Manufacturing ERP Software

Automate Your Operations with Our Leading Bakery ERP System

What Are the Key Challenges in Bakery Manufacturing?

The bakery industry is witnessing rapid transformation fueled by shifting consumer preferences toward healthier, clean-label, organic, and allergen-free baked products. Manufacturers must constantly innovate while maintaining operational efficiency and compliance with stringent industry regulations.

Common Challenges in the Bakery Sector:

- Rising demand for natural and reduced-calorie options without compromising taste.

- Quick turnaround for product development to meet retailer and consumer expectations.

- Stringent allergen requirements, certifications (Kosher, Halal, organic, non-GMO), and shelf-life regulations.

A purpose-built ERP for bakery industry streamlines these complexities, empowering businesses to optimize workflows, enhance product quality, and ensure food safety from raw material sourcing to finished goods distribution.

Ready to Improve your Bakery Operations? - Schedule a Free Demo Now!

Food Industry

Why Bakery Manufacturing Businesses Need a Tailored ERP Solution?

A generic ERP doesn’t address the nuanced needs of bakery production. BatchMaster’s bakery ERP software is engineered to manage every stage of the bakery manufacturing process — from ingredient sourcing and recipe formulation to baking, packaging, warehousing, and beyond.

How BatchMaster’s Bakery ERP Software Supports the Industry:

- Covers end-to-end production: mixing, proofing, scoring, baking, slicing, cooling, and packaging.

- Supports multiple business models: own-brand manufacturing, contract manufacturing, and private-label baking.

- Handles product costing, production scheduling, quality control, and regulatory reporting.

- Enables real-time batch monitoring, allergen tracking, and inventory traceability software integration.

Whether you’re producing fresh bread, pastries, cookies, or snack bars, this bakery manufacturing ERP software gives you complete visibility and control across the supply chain.

It also integrates effortlessly with popular financial platforms such as SAP Business One, Sage, QuickBooks, and Tally.ERP 9, ensuring a smooth transition from standalone bakery software to a full-fledged food ERP software.

Transform Your Bakery Manufacturing Business with BatchMaster ERP

Unlock Predictive Insights, Drive Success, and Achieve Amazing Results!

Key Features of BatchMaster Bakery Production Software

BatchMaster’s bakery production software is packed with industry-specific features designed to optimize every operational aspect of bakery manufacturing:

- Recipe Management: Manage recipes with precise inputs, processes, and quality parameters.

- Flexible Recipes: Use one recipe for multiple products and packaging formats.

- Multiple Packaging Options: Employ the same formula across various BOMs for efficiency.

- Multi-UOM Support: Handle ingredients and products in varied units of measure.

- Ingredient Adjustment: Adjust proportions based on potency, grade, or moisture.

- Costing & Tracking: Track co-products, by-products, and ensure accurate costing.

- Quality Assurance: Conduct checks for compliance with defined standards.

- Inventory Control: Use FIFO/LIFO and track stock by expiration dates.

- Allergen Compliance: Trace allergens for USDA, FDA, and GFSI requirements.

- Yield & Scaling: Predict yields, scale production, and control costs effectively.

- Bi-directional Traceability: Ensure traceability for recalls and audits.

Benefits of ERP Software for Bakery Manufacturing

- Improved Supplier Network: Bakery ERP streamline communication and collaboration with suppliers, resulting in faster sourcing, reduced lead times, and better negotiation power for acquiring quality ingredients at competitive prices.

- Enhanced Transparency at All Levels: Access to real-time data and centralized information allows stakeholders to make informed decisions, providing visibility into inventory levels, production schedules, and quality control measures across the bakery operations.

- Better Availability of Products: Efficient inventory management and optimized production processes ensure consistent product availability, reducing stockouts and meeting customer demands more effectively.

- Reduction in Costs: By optimizing processes, minimizing waste, and enabling accurate forecasting, ERP software contributes to cost reductions in production, inventory management, and procurement, resulting in improved profitability.

- Smooth Supply Chain Management: Bakery ERP systems facilitate end-to-end supply chain visibility, ensuring smoother logistics, minimized disruptions, and enhanced coordination among different stages of production, distribution, and sales.

- Optimization of Processes: Streamlined workflows, automation of routine tasks, and data-driven insights enable process optimization, enhancing efficiency, reducing errors, and allowing resources to be allocated more effectively.

Get Your Free Industry Brochure

See BatchMaster ERP in Action – Book Your Free Demo Now

See how BatchMaster ERP streamlines compliance, enhances workflows, and drives faster, smarter food operations.

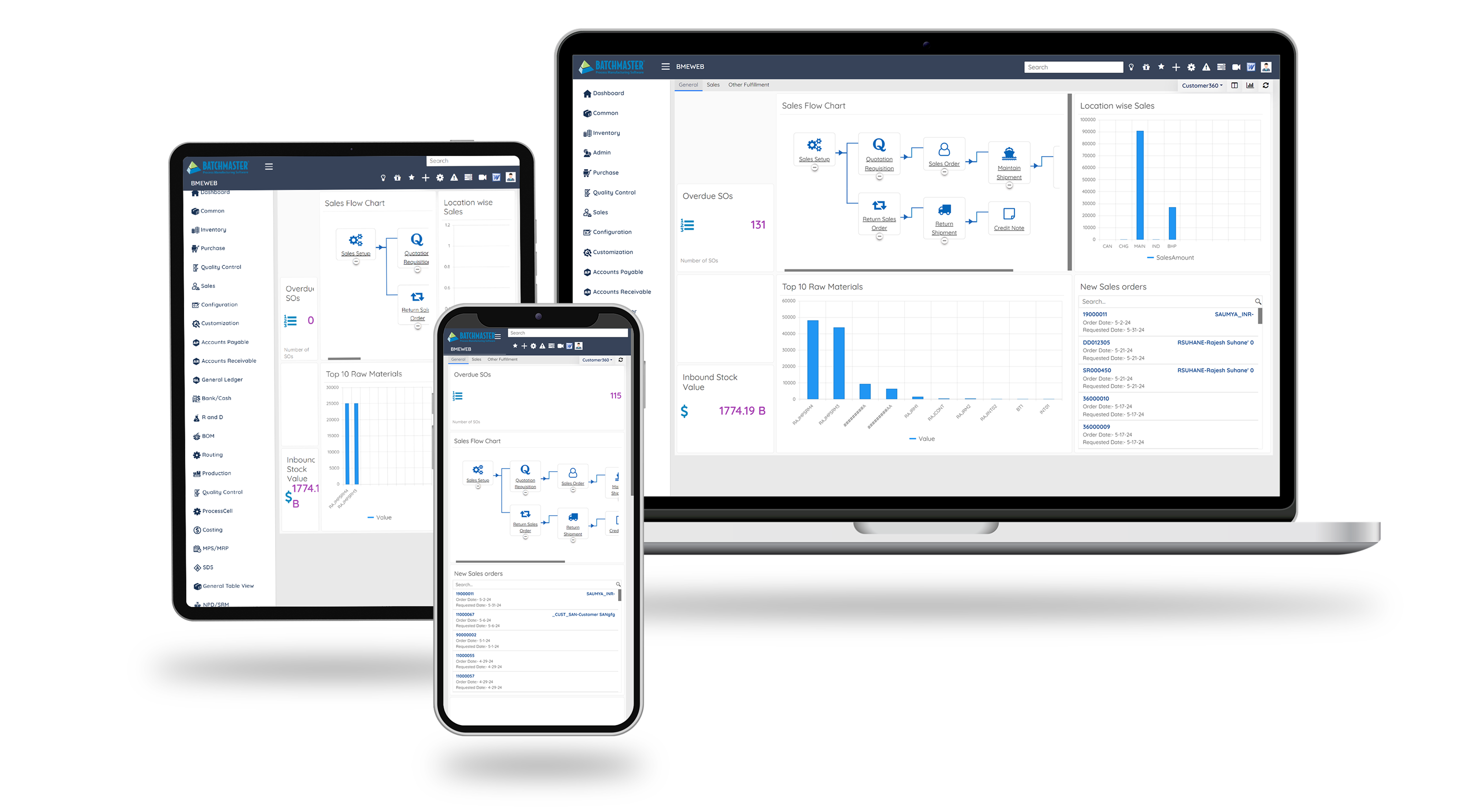

Run Our Manufacturing ERP With Your Existing Financials

Upgrade to our ERP without missing a beat in your financial and accounting routines. BatchMaster ERP offers seamless integration with Tally, QuickBooks, Sage 50/100/200/300, SAP Business One and other popular systems, ensuring a smooth transition.

Looking To Find Best Solution for Your Business?

Allow our expert team of solution consultants to review your business operations so that they can offer you the best-possible solution, either on premise or in the cloud, to meet all your industry-specific needs