Plant-based Meat ERP Software

Amidst growing health concerns globally, people have started shifting their consciousness towards more sustainable food options. In response to this, with the rise of plant-based meat products, the food industry has undergone a remarkable transformation. This transformation seems to rule the industry for years in the future.

But, to thrive in this dynamic and competitive market, apart from culinary expertise, manufacturers need to have efficient and adaptable business processes as well. For this, ERP for Plant-based meat manufacturing industry proves to be a comprehensive and effective solution.

In the subsequent sections of our blog, delve deeper knowing the role of ERP in Plant-based meat industry.

Introduction

Protein acts as the building block for human body, and non-veg dishes are the concentrated source of all essential nutrients. It not only is high in protein but is also considered as the “complete protein”, which includes the same balance of amino acids a human body requires.

Ironically, animals that provide us meat such as, birds, cows, fish, goat, etc., primarily get their nutrition from plants, making them an excellent source of protein. However, plants may be high in protein but don’t necessarily have the required quantity of amino acids. This might be the reason why non-veg is the preferred option for many.

But it is also necessary to take note of the fact that, besides keeping the nutrient and mineral insufficiencies under control, excessive consumption of non-veg nourishments in your day-to-day diet acts as one of the essential triggers for many diseases.

In response, a wave of innovation in the manufacturing industry, gave birth to meat alternatives. These products try to replicate the taste, texture, and the nutritional benefits of the meat. Meat alternatives generally fall into one of the three categories-

- Plant-based

- Fermentation-based

- Cell-based

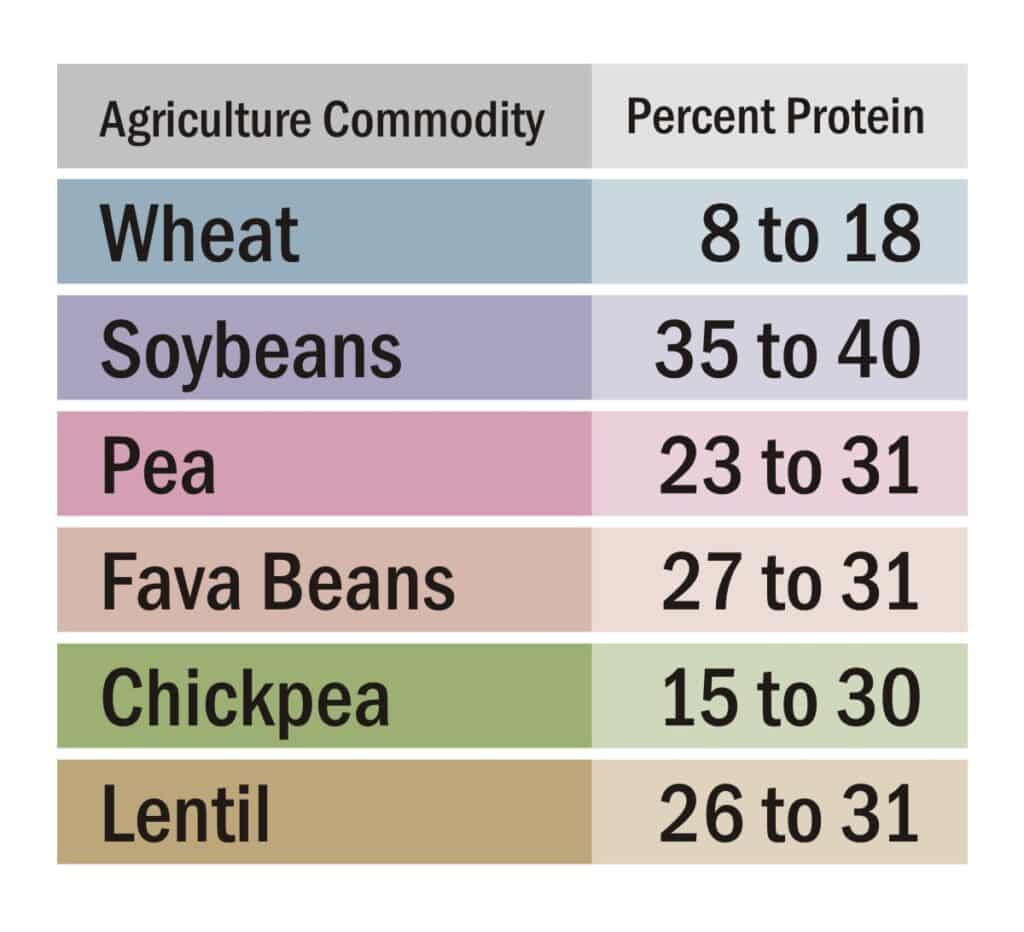

Currently, the most common and widely accepted meat alternative amongst all the above is plant-based meat. It is commonly made from the combination of protein sources such as soy protein, pea protein, wheat gluten, etc, bearing varying amounts of protein.

Plant Based Meat Manufacturing - A Sour Bite

You must be wondering about my choice of describing the manufacturing process as a "sour bite." The rationale behind this expression lies in the complexity of replicating traditional meat, which is not an easy task.

It is a meticulous and precise blend of ingredients performed under specific conditions to achieve all the characteristics of a traditional meat. The key ingredients used in the manufacturing of plant-based meat include plant proteins, fats, flavourings, and binders.

The entire manufacturing process is categorized into three different parts-

- Firstly, creating a meat like structure -

- Secondly, creating a meat-like appearance -

- Lastly, creating the traditional meat flavour -

All the three stages involve execution of numerous intricate processes such as-

- Selection of plant proteins

- Protein extraction and isolation

- Texturization and Structuring

- Flavouring and Seasoning

- Binder Addition

- Colour Enhancement

- Mixing and Homogenization

- Forming and Shaping

- Cooking and Packaging

The true challenges emerge during the execution of these tasks. For manufacturers, the struggle begins right from the initial step of selecting plant-protein sources. This is because the structure and functionality of the Plant based meat alternative (PBMA) depends majorly on protein properties. The ability to retain moisture content, gelation, and solubilizing capabilities are the ones manufacturers need to look for.

Challenges - in Premixing

Complexity takes a new turn at the time of “premixing.” This is one of the dynamic steps involved in the manufacturing of PBMA. The base mix of PBMA contains over 30 different ingredients including protein, fats, fibres, and flavourings having disparate physical and functional properties such as moisture content, particle size, rheology, and stability.

Maintaining consistency of this premix is crucial to ensure uniformity in the quality of the final product. This is what manufacturers often fail to achieve.

Challenges during Thermal Processing-

Next to this, the thermal processing task introduces unique complexities. However, the real meat requires only one-time thermal processing, while the PBMA requires much more thermal treatments.

At an optimum processing temperature of around 95 degrees Celsius, the raw materials are rotated at 20 RPM to improve the fibre structure and make it look similar like traditional meat.

Since each ingredient responds differently to heat, the manufacturers need to maintain precise temperature during thermal processing, ensuring uniform cooking of the product.

Challenges in Colour and Flavour Formation-

Lastly, attaining meat like colour proves to be a challenging task. Colour significantly influences the perception in taste, as it is the first thing to get noticed in food. Poor or inaccurate colour of any recipe might turn off consumer’s decision of buying.

Most of the protein sources are yellow or beige in colour. Hence manufacturers need to add other supplementary ingredients such as beet juice to obtain the required red colour. Furthermore, flavour formation process comes into play.

Manufacturers need to incorporate various spices, herbs, vitamin thiamine, and amino acids to replicate the meat-like flavour and aroma. But to achieve the desired impact of flavour and aroma, it requires careful calibration of these additives, which proves challenging and time-consuming too if failed.

ERP is the Secret Ingredient-

Considering all these challenges and complexities, manufacturers look for new application or technology like automation to curb all these issues swiftly. An Enterprise Resource Planning Software i.e., an ERP for plant-based meat seems to be the perfect solution.

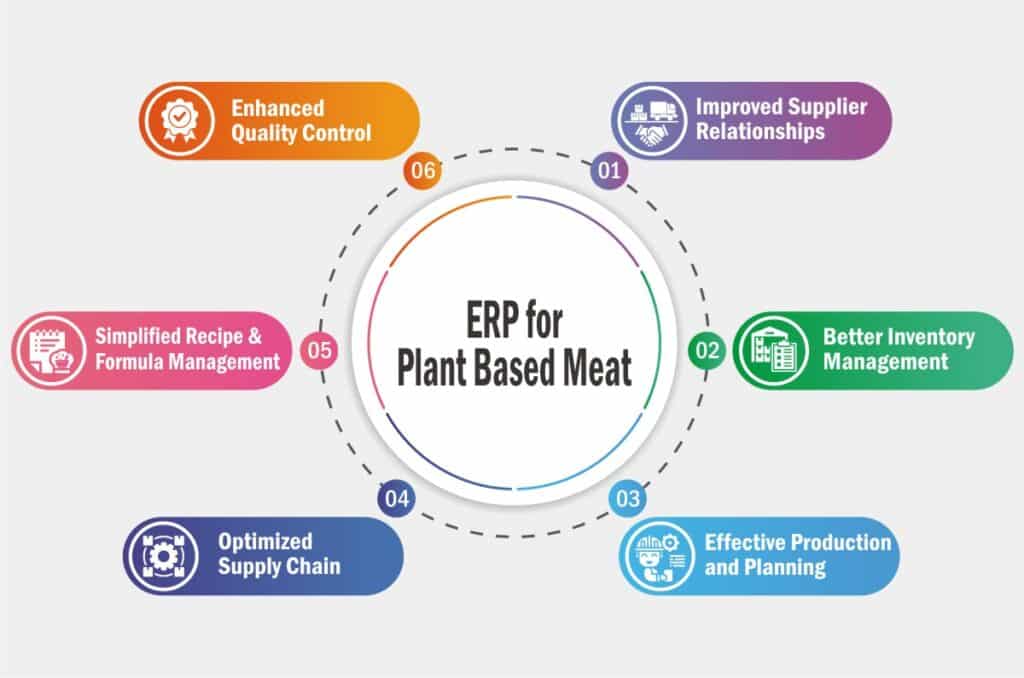

Let’s examine the key functionalities of such software that can help you streamline your manufacturing operations and roll out improved quality of plant-based meat products in the market.

Improved Supplier Relationships-

As it is already discussed, a lot of ingredients are used during the manufacturing of plant-based meat. Ensuring efficient and safe sourcing of these ingredients is necessary, but managing the huge network of vendors represents a real headache.

A plant-based meat ERP handles this in a streamlined and simplified manner. It offers a fully integrated database that allows you to enter, maintain, and monitor all the vital information about your vendors and suppliers.

It also facilitates in vendor selection process by evaluating vendors’ performances based on delivery time, material quality, price, availability, etc.

Better Inventory Management-

Proteins, plant oils, vegetables, herbs & spices, and other perishable ingredients used in plant-based meat manufacturing need to be stored safely, following the required storage conditions.

An ERP for plant-based meat manufacturing helps store all these ingredients efficiently. It provides real-time visibility into the inventory aiding quarantine and specification of storing conditions. This helps manufacturers maintain optimum stock of their inventory all-the-time, preventing shortages, overstocking, wastage and spillage.

Moreover, it also facilitates in better inventory management by tracking expiry dates of materials, issuing them according to FIFO, LIFO methods, minimizing spoilage and hence securing profits.

Effective Production and Planning-

The ERP for plant-based meat manufacturing helps in scheduling thermal processing batches efficiently. By considering the parameters such as processing time, required temperature, rotations, and equipment availability, the system automatically creates optimized schedules, minimizing lead times and enhancing overall production productivity.

Optimized Supply Chain-

Today consumer is increasingly health conscious and makes sustainable choices. Thus, to set themselves apart, manufacturers need to ensure sustainability throughout the supply chain. Plant based meat ERP systems offers you the capability of overseeing your complete supply chain activities, handling the waste effectively and disposing them off as per the set standards.

It allows you to view your entire supply chain, from farm to fork. Through its real-time visibility functionality, it minimizes wastage and ensures fresh ingredients are used.

Simplified Recipe & Formula Management-

The plant-based meat manufacturing industry is new and demands extensive R&D to test many different variations of the formulas. Moreover, it dynamically calculates various nutritional property values and helps perform what-if analysis to achieve targeted values of protein, fats, and such. Relieving you of complex calculations yet ensuring precision.

A food manufacturing ERP software with its robust formulation module helps plan based meat manufacturers create, store, and access thousands of recipes along with their multiple versions, increasing accuracy and productivity.

Moreover, it allows plant-based meat manufacturers to precisely calibrate the quantities of all the supplementary ingredients. It also allows to adjust their quantities to meet dietary preferences and ensure regulatory guidelines.

Enhanced Quality Control-

A plant-based ERP system follows rigorous quality controlling measures such as-

- Processes Standardization- It establishes standardized manufacturing processes based on industry best practices and regulatory standards, ensuring consistency and uniformity.

- Automated Quality Checks- It allows to implement multiple quality checks and inspections based on colour and flavour at various stages of production. This reduces the possibility of errors to a great extent.

- Real-Time Monitoring- ERP for plant-based meat provides the capability of real-time monitoring of production processes. Manufacturers can track crucial parameters like temperature, pressure, and ingredient proportions, and get immediate alerts in case of deviations from the set standards.

- Batch Traceability- The plant-based meat ERP system enables the capability of batch traceability, allowing manufacturers to trace the origin of ingredients and track the journey of each batch along the various processes of meat production from initiation to extraction, texturization, seasoning including all steps in between to cooking and packing.

Moreover, it also verifies recipes against approved allergen standards and ensures that product labels are generated in standard formats plus accurately reflect the presence of allergens.

Final Thoughts -

The rapidly expanding landscape of plant-based meat manufacturing offers boundless opportunities for growth. Within this dynamic sector, manufacturers are searching for the right technology to streamline operations, reduce wastage, boost productivity, and ensure profitability.

One such technologically advanced software is BatchMaster ERP, Its numerous capabilities empower plant-based meat manufacturers to perform every operation efficiently.

Curious to know more about it? Get in touch with our team of experts today!