ERP System for Sugar Industry

BatchMaster ERP for Sugar Industry

The sugar industry is a process manufacturing industry involving several processes and stages before it hits the market. Being a multi-staged manufacturing type by nature, it has to manage the procurement of sugar cane from farmers or the cultivation of sugar cane on a large scale to deliver packed sugar to buyers or consumers.

To do this, they also need a big distribution network that connects the suppliers, makers, storages, and sellers to the final buyer.

And so, to smoothen this entire trail from procuring sugar cane to delivering the final product (sugar) to end users, they require a solution that effortlessly does it for them. Basically, they need a customized ERP software for the sugar industry that can streamline the entire supply chain and also help eliminate the challenges sugar manufacturers face.

In this blog, we will learn how a Food ERP software empowers sugar manufacturers to streamline supply chains and overcome challenges. Keep reading –

Schedule a Demo of BatchMaster Bakery ERP Software

Food Industry

The Sugar Industry in India

Sugar is one of the most essential ingredients in Indian households. It is also a crucial raw material for industries like food and beverages in producing products such as cakes, ketchup, cold drinks, etc.

Yield-wise, India stands as one of the world’s largest sugar producers. Annually, the country produces around 359 LMT (lakh metric tons) of sugar.

The Indian sugar industry has two sectors: organized (sugar factories) and unorganized (traditional sweetener producers like Gur and Khaand).

This sector holds significant importance because of its contribution to employment. Approximately 500,000 workers are employed in sugar mills. Additionally, the livelihoods of approximately 50 million rural sugarcane farmers are reliant on this industry. Moreover, secondary activities such as transportation, machinery servicing, trade, and agriculture supply chains further contribute to job creation.

The process of sugar manufacturing in India heavily relies on manual labor, involving various labor-intensive steps. Consequently, there is a growing need for automation to address the industry's increasing demand and supply dynamics. Using the power of sugar ERP software and automating these activities can significantly enhance efficiency and support the sector's sustainable growth.

What is Sugar ERP Software?

A Sugar ERP software is a modular business management software that streamlines business tasks in real-time. It helps with accessing data easily, allowing different departments to collaborate smoothly and be on the same page. This results in improving efficiency and productivity in the entire workflow of the organization.

Sugar ERP manages the entire process of sugar production, from acquiring sugarcanes to manufacturing sugar. It also manages stock and spoilage, checks the quality of the sugar, and tracks sales and customer service.

It covers every aspect of business, like storing harvesting details, sugar & cane billing, budgeting, cane procurement from vendors, cane pricing, inventory management, formulas for making several types of sugar, lab reporting and equipment maintenance, etc.

BatchMaster Software is a Sugar ERP system that automates crucial aspects of the sugar business, from raw material procurement and supply chain management to regulatory compliance, vendor management, production monitoring, reporting, financial accounting, sales tracking, and customer satisfaction. This streamlined approach significantly boosts efficiency, quality, and productivity in sugar manufacturing.

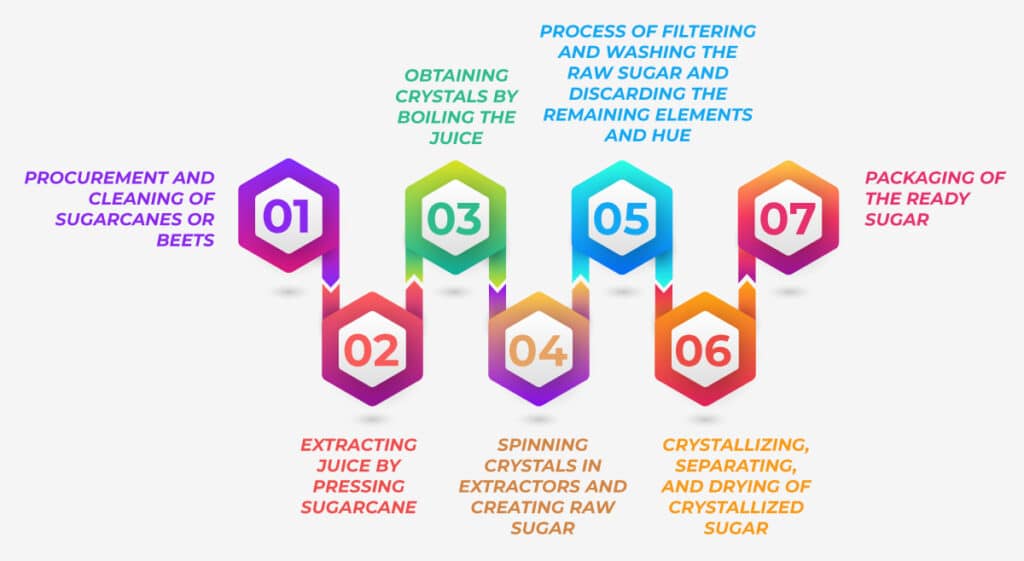

Processes Involved in Sugar Manufacturing

The major processes of sugar manufacturing involve several steps to transform sugar cane or sugar beets into the final product, which is packaged and ready for consumption. Here's an explanation of each step and how sugar ERP helps:

Procurement and cleaning of sugarcanes or beets:

This step involves acquiring the raw materials, which are sugarcanes or sugar beets. The raw materials are thoroughly cleaned to remove dirt and impurities, preparing them for processing. Here a sugar ERP can be of immense help as it streamlines the procurement activities by automating purchase orders, optimizing inventory, and facilitating supplier collaboration.

Extracting juice by pressing sugarcane:

In this stage, the cleaned sugarcanes are crushed or pressed to extract the sugary juice contained within. The extracted juice is typically rich in sugar and serves as the starting point for sugar production.

This extracted sugar should be of the finest quality and for that ERP can help in evaluating the samples and reject the ones that do not match the quality standards. Not just at the extraction phase, an ERP manages the entire production process and ensures that quality is never compromised.

Many sugar products are produced in batches. ERP systems facilitate batch management, ensuring that each batch is documented and enable real-time tracking of production processes. This helps in monitoring the progress of production orders, identifying bottlenecks, and adjusting as needed to meet the production goals.

Obtaining crystals by boiling the juice:

The sugary juice obtained from the previous step is boiled to concentrate the sugar content. As the juice is heated and water evaporates, sugar crystals start forming in the thickened liquid.

Spinning crystals in extractors and creating raw sugar:

The sugar crystals are separated from the remaining liquid using extractors, which are typically centrifuges. The result is a product known as raw sugar, which still contains some impurities and moisture.

Process of filtering and washing the raw sugar and discarding the remaining elements and hue:

Raw sugar undergoes a process of filtration and washing to remove impurities and any remaining non-sugar elements. This step helps improve the purity of the sugar and eliminate unwanted substances.

Crystallizing, separating, and drying of crystallized sugar:

The filtered and washed sugar is further crystallized to enhance its purity and granulation. The sugar crystals are separated and dried to reduce their moisture content, resulting in high-quality crystallized sugar.

Packaging of the ready sugar:

Finally, the dried and crystallized sugar is packaged into many sizes and formats suitable for distribution and consumption. This packaging ensures the sugar is protected and ready for sale to consumers or other industries that use sugar as an ingredient.

As soon as the sugar is produced, it needs to be maintained at a certain level of temperature conditions. Also, the packaging must be done according to the unit of measurements decided. For e.g.: 100 gms, 500 gms, 1 kg etc. To manage this, sugar ERP helps with the proper labeling and multiple packaging of the sugar products.

These major processes of sugar manufacturing are essential for transforming raw sugar cane or sugar beets into the refined sugar product that we commonly use in various culinary and industrial applications. Each step is carefully managed to produce sugar of the desired quality and consistency.

Here, sugar ERP software plays a particularly important role. It oversees the entire journey of sugar production, starting from the procurement and cleaning of sugarcanes or beets, juice extraction, crystallization, filtration, and washing, all the way to the packaging and distribution of the final refined sugar product.

Issues faced by Sugar Manufacturers without a Sugar ERP Software

The sugar industry faces numerous challenges, both internal and external, such as management and interaction with farmers/vendor, local authorities, and shippers. Adding to it are problems such as weather changes, stringent getting regulation, price fluctuations, varying demands, short seasons, complex production, et al. These complexities necessitate the use of a sugar ERP system.

Moreover, producing sugar is costly because of the factors such as expensive raw materials, outdated technology, and labor-intensive manual processes. Sugar companies often have difficulty managing costs and staying competitive because of the pressure of operating at lower capacity, which affects their profitability.

Smaller sugar companies struggle to cut costs as they miss a number of factors enjoyed by larger operations. For example, bigger players can secure cost-effective resources in off season, benefits from high capacity and greater number of runs during production and can distribute expenses more effectively which gives them a competitive edge. Smaller firms lack these advantages, often struggle to keep their costs down and compete in the sugar industry.

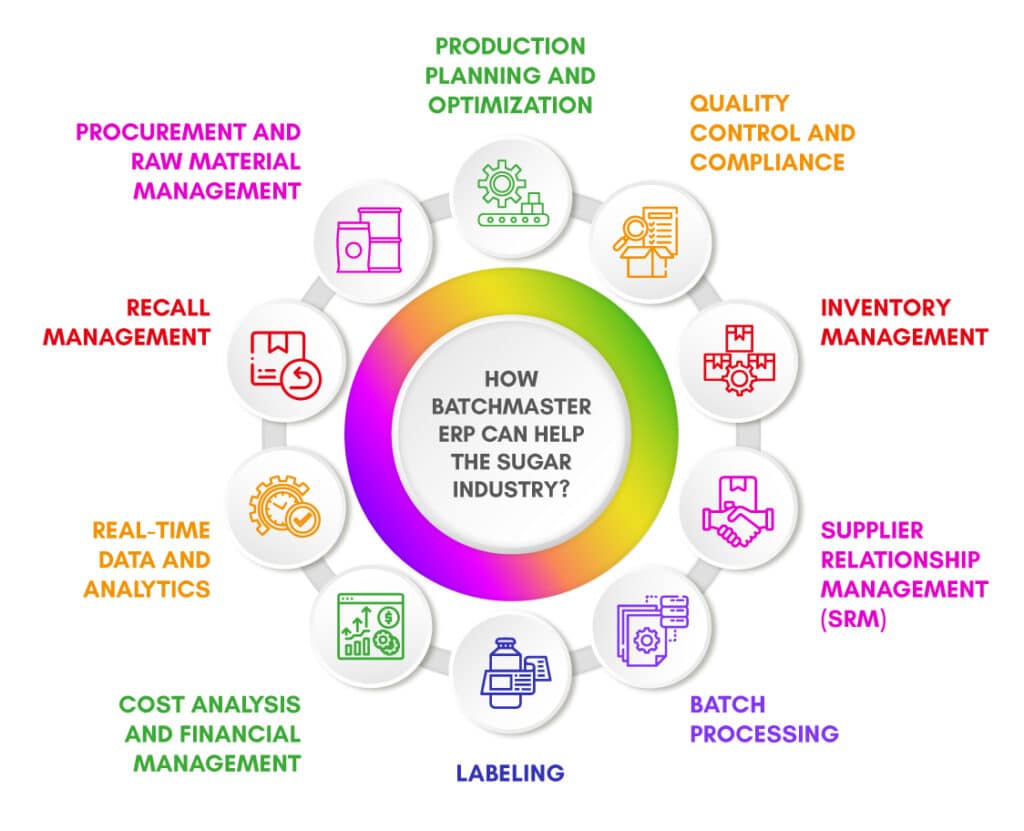

How BatchMaster ERP can help the Sugar Industry?

BatchMaster ERP offers a set of tools designed specifically for sugar companies, both big and small. These tools help streamline operations, make supply chains agile, ensure quality, and provide real-time data for smart decisions. This software can benefit sugar businesses by assisting with challenges, opportunities, and daily operations.

For example, one specific challenge in the sugar industry is the short crushing season, limiting the time available to process sugarcane into sugar. ERP software like BatchMaster ERP can overcome this challenge by optimizing production schedules, resource allocation, and inventory management.

It allows for efficient planning and utilization of available time and resources during the brief crushing season, ensuring maximum sugar production in a limited timeframe.

Here are some more reasons why BatchMaster ERP is the apt choice for the sugar industry

Procurement and Raw Material Management:

BatchMaster ERP allows sugar companies to efficiently manage the procurement of sugarcane or sugar beets. It can efficiently plan raw material requirements based on forecast, customer orders, requirement at other plants/warehouses, production demand, etc. Based on this it can help you procure material when it is available at profitable rates.

Production Planning and Optimization:

This Sugar ERP software records all the relevant production details for each batch of sugar, including the source of raw materials, processing steps, quality control checks, and any deviations from standard procedures.

Moreover, it also helps in planning production schedules based on demand, raw material availability, and production capacity. For eg, if there's a surge in demand for sugar during the holiday season, the ERP system can adjust production accordingly to meet customer needs.

Quality Control and Compliance:

It can incorporate quality control checks at various stages of production to ensure that the sugar meets industry standards. Be it monitoring sugar crystal size, color, and purity levels or numerous other tests that help to maintain consistent product quality and comply with regulatory requirements, Sugar ERP like BatchMaster ERP can help you apply all If any parameter falls out of the acceptable range, the system triggers alert(s) to prevent substandard products from being produced.

Further, ERP software for sugar can store and update information on regulatory requirements from various regions and authorities. For example, it can keep track of changes in food safety regulations like FDA, FSSAI, cGMP etc.

Inventory Management:

The software also helps in optimizing inventory levels of both raw materials and finished products. It ensures that the products are arranged and organized efficiently to avoid delays in deliveries. Example - System automatically generates purchase orders for sugarcane when stock levels follow below the reorder Point.

It even tracks the expiry/shelf life of products and allows issuing them based on LIFO, FIFO, FEFO, or whatever method your business follows, reducing wastage and increasing profits.

Supplier Relationship Management (SRM):

It facilitates better communication and collaboration with sugarcane or sugar beet suppliers. The company can conduct background checks and also track supplier performance, negotiate contracts, and resolve disputes, fostering stronger relationships and ensuring a stable supply of raw materials.

For example, they can assure customers that their sugar comes from a specific source or meets certain quality standards.

Batch Processing:

Sugar ERP software helps with batch processing in the sugar industry by automating and optimizing key tasks such as batch formulation, scheduling, and quality control. It ensures accurate ingredient measurements, precise batch calculations, and efficient process monitoring. This not only reduces manual errors but also increases production n efficiency, resulting in consistent high-quality sugar products.

Labeling:

Sugar ERP simplifies labeling by offering customizable templates, automating data population, determining allergens, supporting multi-language labels et al. These labels can be generated in the standard FDA formats or can be customized to meet industry/country/regulatory norms.

Cost Analysis and Financial Management:

BatchMaster ERP provides detailed cost analysis reports, allowing sugar companies to identify areas where cost savings can be achieved. It can show the cost breakdown of each production batch, helping management make informed decisions to reduce overhead expenses.

The software also helps with streamlining all the accounting activities and is capable of integrating 3rd party financial software within itself.

Real-Time Data and Analytics:

This software provides real-time data and analytics dashboards that enable sugar companies to monitor supply chain performance. For example, they can track the time it takes to move sugar from production to distribution and identify bottlenecks in the supply chain for optimization.

Recall Management:

In any case of quality issues or safety concerns, lot traceability allows sugar companies to quickly identify affected batches. ERP systems can trace the origin of each batch of sugarcane or sugar beets, recording information about the supplier, date of harvest, batch number in which it was produced, quality assessments, and the customer to whom it was delivered. This enables faster recalls, reducing its impact and cost while protecting consumers.

Final Words

BatchMaster ERP offers a suite of tools designed explicitly for sugar companies, enabling them to optimize operations, enhance supply chain efficiency, ensure product quality, and access real-time data for informed decision-making.

In the journey from sugarcane fields to the market shelves, BatchMaster ERP for the sugar industry serves as a dependable partner, simplifying complexities, reducing costs, and enabling sustainable growth. With the right ERP software in place, sugar manufacturers can sweeten their operations, meet market demands, and thrive in this dynamic sector. About Us