BATCHMASTER ERP for Cement

What are the Challenges for Cement Manufacturing Industry?

The cement industry demands a tight control over operations, end-to-end. The manufacturers need to ensure a hassle-free supply chain, and monitor the inventory in real-time from raw material procurement to shipping for a smoother operational flow. It’s also important to manage raw material and fuel requirements for uninterrupted production batches, back to back. Also, manufacturers focus lies on scheduled maintenance and preventive methods so that the process cells are always functional and downtime in minimized.

The industry even encounters stringent regulatory compliances related to environment and following safe manufacturing practices for the labors. This shows a dire need to shun the manual methods of managing business and opting a business-performance software that streamlines the operational processes plus increases workflow efficiency—developing an optimized industry environment.

Would you like to learn more about our Cement ERP Software?

Chemical Industry

Why Cement Manufacturing Businesses Require ERP Software?

BatchMaster ERP is the ideal ERP for chemical industry that provides top-notch end-to-end supply chain management software, understands cement manufacturing processes well and focusses on formula version control, substitution, physical property analysis along with adhering to all the mandatory regulatory compliances. It allows manufacturers to maintain optimum temperature, pressure and suitable angle in the cement kiln along with predicting the rate of chemical reaction based on the quantities of raw material to form molten lava and cement clinkers on cooling.

Moreover, it regulates the addition of intermediates like gypsum (3% or 5%) to manage the setting time, permeability, resistance to sulfates and aggressive environmental condition, workability, or higher-quality finishes of cement. BatchMaster’s efficient Planning and Scheduling modules make timely procurements and keep wastage at bay. A number of quality tests can be applied on raw materials, formulas, processes as well as final product at different points in supply chain, simply on a click of a button.

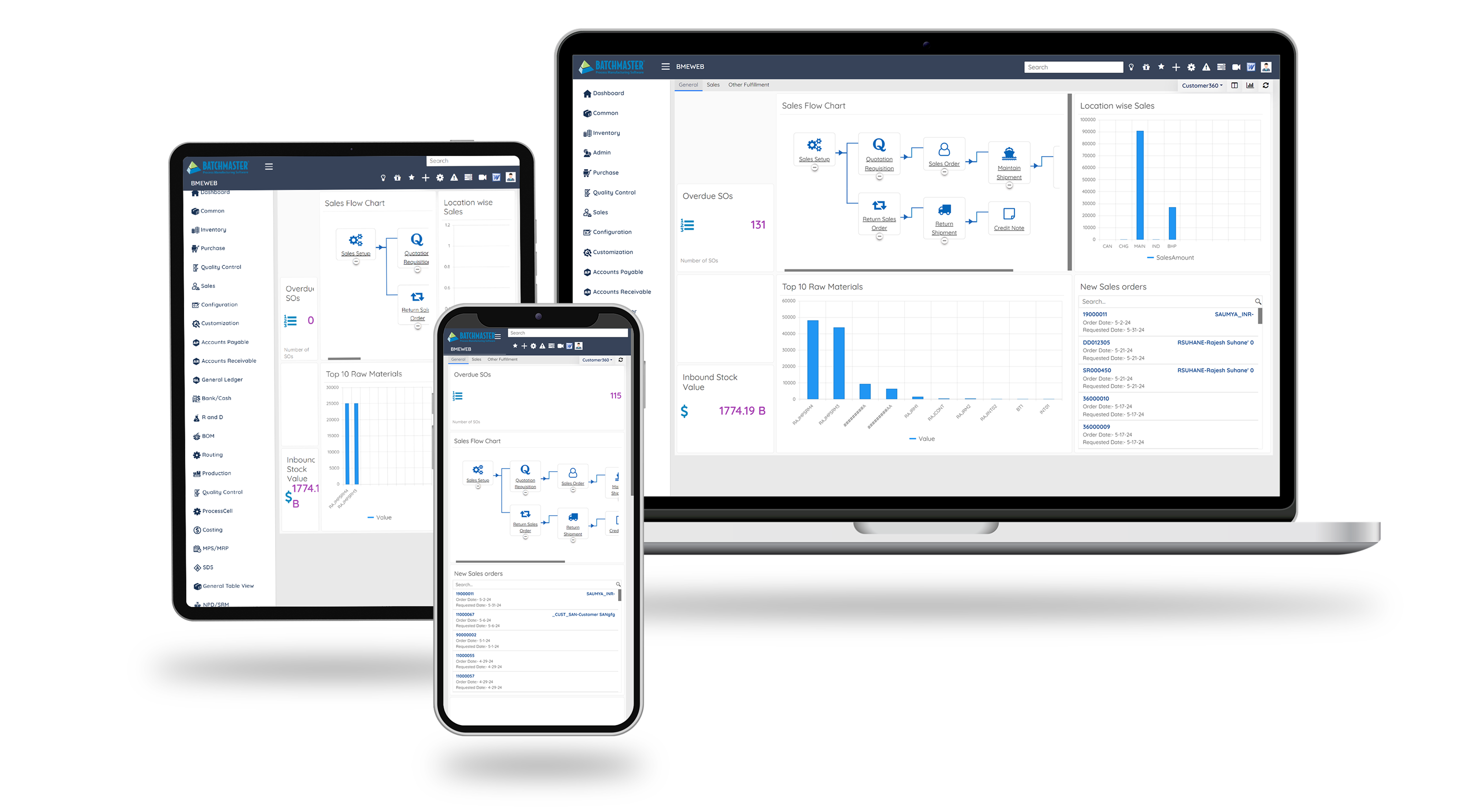

Our products have a proven integration to SAP Business One, Sage 50/100/200/300, QuickBooks, and Tally.ERP 9 which means you can easily upgrade to BatchMaster without having to shun your financial software.

Transform Your Cement Manufacturing Business with BatchMaster ERP

Unlock Predictive Insights, Drive Success, and Achieve Amazing Results!

Key Features of ERP Software for Cement Industry

- Formula Design Based on Physical Properties analysis like strength of the ore

- Formula Security to Support Intellectual Property Rights

- Supports FDA and other Compliance Requirements

- Label printing & List of ingredients

- HAZMAT Bills of Lading, VOC, and SARA Reporting

- BOM and suitable Packaging Options

- Bi-directional Lot Traceability

- Vendor Approval and Management

- Stability or setting time Testing

- Non-Conformance and CAPA

- Complete Traceability and Costing products

- Customized COA (Certificate of Analysis) Reports

- Separate Costing of Formula and Packaging Materials

- New Product Development, Sample Management and Costing

- Warehouse Management and real time tracking of inventory movement

- Material substitution in formula and Revision Tracking

- Supports Multiple Units Of Measure

- Material Production Scheduling (MPS) Material Requirement Panning (MRP) for optimum raw material procurement and order processing

- Make-To-Stock and Make-To-Order Operations

- Contract Manufacturing and Loan Licensing

Benefits of BatchMaster ERP for Cement Manufacturers

- Control Your Business End-to-End.

- Deliver cement to your customers on time, every time.

- Keep your plant up and running 24x7.

- Manage your operations efficiently.

- Use power optimally.

- Reduce cost.

- Meet raw material requirements efficiently.

Brochures

Run Our Manufacturing ERP With Your Existing Financials

Upgrade to our ERP without missing a beat in your financial and accounting routines. BatchMaster ERP offers seamless integration with Tally, QuickBooks, Sage 50/100/200/300, SAP Business One and other popular systems, ensuring a smooth transition.

Web/Cloud Deployment Available

Give your small, mid-size, or large-scale businesses the power of our ‘Cloud ERP’ solutions, and enjoy the benefits of leveraging the cloud.

Looking To Find Best Solution for Your Business?

Allow our expert team of solution consultants to review your business operations so that they can offer you the best-possible solution, either on premise or in the cloud, to meet all your industry-specific needs