BATCHMASTER ERP for Epoxy & Resins

What are the Challenges in Epoxy & Resins Manufacturing?

Increased R&D and technological advancements in industries like paint & coatings, constructions, transportation, aerospace, electrical & electronic laminates, marine coatings, composites and decorative powder coatings etc., which are heavy application segments for epoxy & resins are likely to drive the industry demand.

Moreover, increased wind energy capacity installation has also fueled the demand for epoxy & resins. However, volatility in raw material prices, easy availability of substitutes such as polyurethane and phenolic resins, environmental concerns, adherence to strict regulations and emission standards further hamper the manufacturers’ routine activities.

Would you like to learn more about our ERP for Epoxy & Resins?

Chemical Industry

Industry-Specific Epoxy & Resins Manufacturing ERP Software

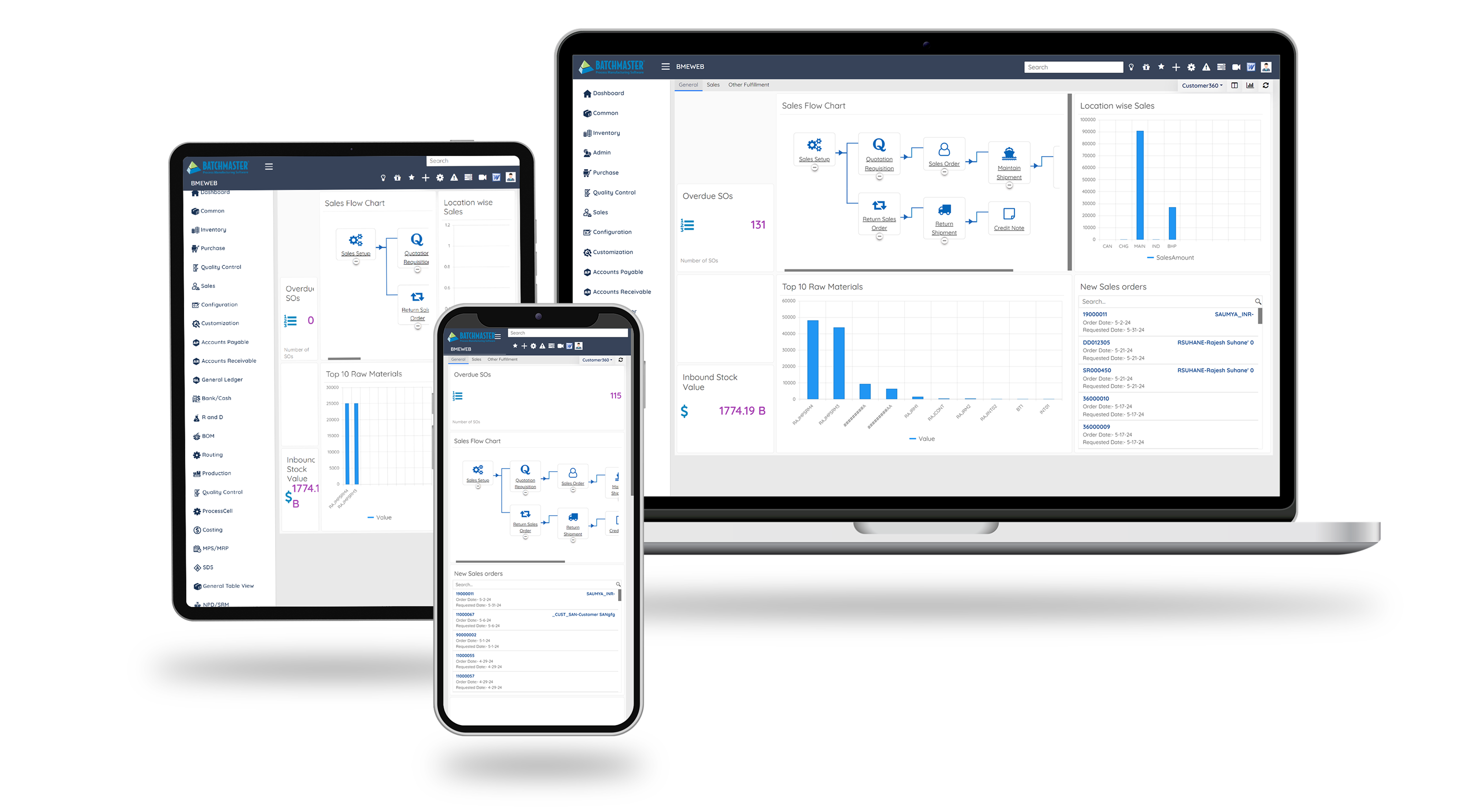

BatchMaster ERP, is a true process-centric chemical manufacturing ERP solution that streamlines all supply chain functions like formula management and security, production, purchase, sales, material and production planning, delivery and such. It even efficiently handles vendor management, by-product and co-product management, warehouse management, along with HMIS support for safety of workers, intensive quality control, etc. It also helps manufacturers to meet regulatory compliances such as OSHA Hazard Communication Standard, REACH, and VOC emissions standards, as well as bi-directional lot traceability several transportation regulations, et al.

Our products have a proven integration to SAP Business One, Sage 50/100/200/300, QuickBooks, and Tally.ERP 9 which means you can easily upgrade to BatchMaster without having to shun your financial software.

Key Features of ERP Software for Epoxy & Resins Manufacturing

- Formula security to support Intellectual Property Rights (IPRs)

- Formula design based on physical properties

- New product development and its costing

- Vendor approval and management

- Batch Production with Runs and provision to create intermediate and fiished product in same batches

- Complete sales cycle support from quote to order to delivery & invoicing

- Separate costing of formula and packaging materials

- Supports OSHA, REACH, EPA, ISO, DOT compliance requirements

- Supports GHS labeling requirements

- Material Production Scheduling (MPS)

- Material Requirement Panning (MRP)

- HAZMAT bills of lading, VOC, and SARA reporting

- Bi-directional lot traceability

- Stability testing

- Non-Conformance and CAPA

- Complete traceability and costing of by and co-products

- Customizable COA (Certificate of Analysis) reports

- Warehouse management

- Shelf life/expiration date support

- Supports multiple units of measure

- Containerization

- Make-to-stock and make-to-order operations

- HMIS support for safety of workers

Benefits of BatchMaster ERP for Epoxy & Resins Manufacturers

- Increased operational efficiency

- Effectively helps to meet regulatory requirements

- Ease of new product development

- Real-time information for pro-active decision making

- Improve customer service levels to retain and gain customer base

- Increase margins and profitability

- Assure 'greener' products

- Avoids unplanned shutdowns

- Brings product faster to market

Run Our Manufacturing ERP With Your Existing Financials

Upgrade to our ERP without missing a beat in your financial and accounting routines. BatchMaster ERP offers seamless integration with Tally, QuickBooks, Sage 50/100/200/300, SAP Business One and other popular systems, ensuring a smooth transition.

Web/Cloud Deployment Available

Give your small, mid-size, or large-scale businesses the power of our ‘Cloud ERP’ solutions, and enjoy the benefits of leveraging the cloud.

Brochures

Looking To Find Best Solution for Your Business?

Allow our expert team of solution consultants to review your business operations so that they can offer you the best-possible solution, either on premise or in the cloud, to meet all your industry-specific needs