ERP Software for Ethanol Manufacturing Industry

Overview

Amidst growing concerns about environmental sustainability and the desire to reduce dependence on fossil fuels, a notable shift has been seen in various industries towards adopting flex fuel.

Flex fuel blends ethanol with traditional gasoline, with variations such as E10 (10% ethanol), E15 (15% ethanol), E85 (85% ethanol), and E100 (100% ethanol), each reflecting different ethanol concentrations.

Despite, the environmental benefits and advantages it offers, the production process of ethanol presents numerous challenges and intricacies. From selecting suitable feedstock (sugar or starch-based feedstock, or cellulosic feedstock) to navigating the complexities of production methodologies, meeting industry standards and regulations, and managing fluctuating market demands, ethanol manufacturers face numerous challenges. Balancing quality, compliance, efficiency, and profitability simultaneously proves to be a daunting task.

BatchMaster ERP Software for the ethanol manufacturing industry provides a comprehensive solution, supporting ethanol businesses throughout their operations. It assists in procurement, inventory management, production planning and scheduling, batch processing, quality control, compliance management, accounting, and distribution.

If you are looking to experience reliability, scalability, accountability, traceability, and profitability then, switch to BatchMaster ERP.

Would you like to learn more about our Ethanol ERP Software?

Chemical Industry

Unmatched Capabilities of Ethanol Manufacturing ERP System

BatchMaster ERP Software for Ethanol Manufacturing provides a competitive advantage to ethanol manufacturers through its outstanding features and capabilities-

Being a pioneer in the formulation module, BatchMaster ERP solution for ethanol industries offers the capability to dynamically adjust formulas to meet the properties of ethanol like viscosity, density, water vapour, etc. It even manages, stores, tracks, secures numerous formulas and their versions while allowing for scaling, substituting, comparing them.

BatchMaster ERP Software for ethanol manufacturing industry allows manufacturers to create flexible production schedules and batches for varying ethanol blends including E5, E15, E85, etc.

Moreover, manufacturers can dynamically specific production requirements for each blend such as batch sizes, raw materials requirements, etc. due to changing customer demand, unavailability of material and such.

By providing tools for monitoring temperature, pressure, time, and other critical variables, BatchMaster ERP solution allows to make timely adjustments during processes like fermentation, distillation, etc. This helps them optimize ethanol yield and quality.

Moreover, ERP stores historical data of every process. By analysing this data, manufacturers can identify trends and patterns, and can adjust parameters or optimize fermentation conditions according to it.

Ethanol ERP streamlines inventory management by tracking raw materials (like corn, sugarcane), chemicals (like acid, yeast, etc), and packaging materials (containers, tanks, jars, etc.). It ensures accurate inventory levels through pallet, lot-, item-level tracking and optimization measures. Real-time visibility and integration with production planning, re-order points, safety stock, etc., facilitate efficient inventory control, minimizing stockouts and production halts.

BatchMaster ERP System for ethanol industry allows QC procurement manager to establish quality parameters such as ethanol concentration, purity levels, moisture content, and impurity limits.

It also provides the capability to conduct QC tests at various checkpoints of the production right from procurement to delivery. Its tools simplify the task of applying tests, capturing QC test results, generating reports, COA generation, etc.

BatchMaster ERP for ethanol manufacturing automates complete compliance management by generating regulatory reports, maintaining documentation, and followng industry regulations. This reduces the risk of penalties and fines.

ERP software for ethanol manufacturing allows to monitor production, storage, and sell of the by-products and co-products that bio-refineries generate like dry distiller grain, carbon-di-oxide, acetone, methyl formate, etc.

Key Features of ERP for Ethanol Industry

- Formula security to support intellectual property rights

- Bi-directional lot traceability

- Shelf life/expiration date support

- Supports multiple units of measure

- Make-to-stock and Make-to-order operations

- Material Production scheduling (MPS)

- Material Requirement Planning (MRP)

- Containerization

- Designing formula according to the physical properties of materials

- Maintaining a complete audit trail of numerous formula versions

- Supports HMIS to ensure worker and end user safety

- Performing what-if analysis and multiple costing methods to ensure increased profit margins

- Precise traceability and costing of co-products and by products

- Ensuring execution of SOPs through inspection checklist for every task

- Planning and procurement of raw materials

Benefits of Ethanol Manufacturing ERP System

BatchMaster ERP Software for Ethanol Manufacturing provides a competitive advantage to ethanol manufacturers through its outstanding features and capabilities-

ERP for ethanol integrates all functions and departments of ethanol manufacturing organization, enabling seamless communication & collaboration across the organization.

The real-time visibility that an Ethanol ERP provides, helps in enhanced decision making at higher level and better responsiveness at other levels.

By controlling wastage, improving workflows, enhancing quality and meeting compliance, an ethanol ERP software helps cut costs related to losses, legal penalties, fines, etc.

Digitizing core & time-consuming operations along with simplifying complex calculations, ERP Software for biofuels enhances overall organizational efficiency and accuracy.

Evaluating every process and product on all the predefined parameters, ERP Software for Ethanol helps deliver consistent output always.

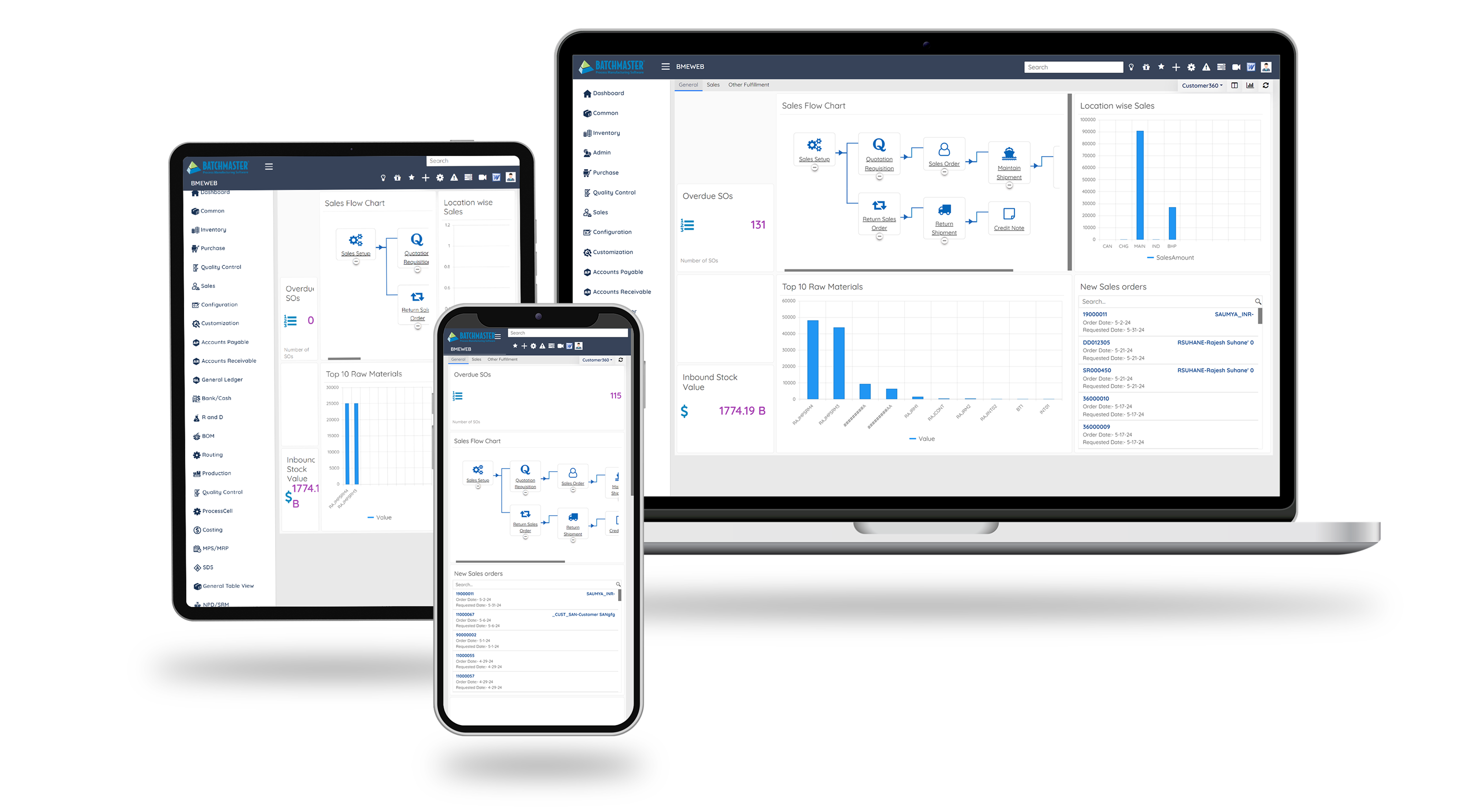

The interactive dashboards of Ethanol ERP Software provide actionable insights about the complete organizational working, ensuring transparency in production processes, employee performances, and raw material availability.

Inflammable nature of ethanol makes this industry risky. An ERP Software for ethanol manufacturing helps maintain HMIS/WHMIS, safety data sheets, and SOPs, ensuring safe working and avoiding danger, both for workers and end-users.

Industries Served by Flex Fuel

Flex fuel is the suitable sought-after alternative to the traditional fuel, it might see its usages in many industries like:

Aviation

Marine

Automobile

Racing sports

Run Our Manufacturing ERP With Your Existing Financials

Upgrade to our ERP without missing a beat in your financial and accounting routines. BatchMaster ERP offers seamless integration with Tally, QuickBooks, Sage 50/100/200/300, SAP Business One and other popular systems, ensuring a smooth transition.

Web/Cloud Deployment Available

Give your small, mid-size, or large-scale businesses the power of our ‘Cloud ERP’ solutions, and enjoy the benefits of leveraging the cloud.

Brochures

Looking To Find Best Solution for Your Business?

Allow our expert team of solution consultants to review your business operations so that they can offer you the best-possible solution, either on premise or in the cloud, to meet all your industry-specific needs